Construction, with its complex operations and ever-evolving demands, has embraced drone technology to streamline processes and enhance productivity. One emerging solution is the Drone-in-a-Box (DiaB) concept, which stands out as a game-changer in certain scenarios. These automated systems promise to revolutionize how construction projects are monitored, surveyed, and managed from start to finish.

In this article, we discuss some of the DiaB solutions available for the construction sector, exploring their functionalities, benefits, and diverse array of choices.

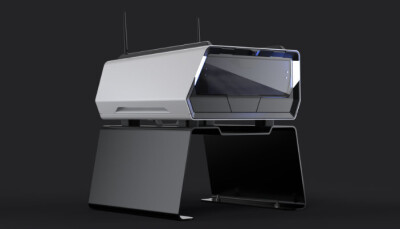

Skydio Dock

Remotely operated and AI-powered, the Skydio Dock allows companies to perform continuous monitoring, recurring inspection, and scheduled patrol, as well as enables remote on-demand visibility. With a footprint of just 4 square feet and weighing only 62 pounds, the Skydio is one of the smallest and lightest docks available, making it easy to deploy in many different environments.

Fully integrated with Skydio’s Remote Ops software, the Dock works seamlessly with Skydio drones connected to Skydio Cloud, providing users with a closed, safe, and reliable ecosystem. Drones paired with the Skydio Dock can also take advantage of Skydio’s Visual Positioning System, which maps its environment in real-time and remembers it for future missions.

By capturing imagery and videos, and streaming data to engineers in real-time, the Dock allows construction companies to monitor progress in more efficient ways. Accurate Drone Solutions, a growing drone service provider serving the construction industry, increased revenue per pilot by 37% by deploying Skydio 2 drones for autonomous mapping of their construction sites. With the Skydio Dock, the company believes it would generate even more revenue by remotely generating data from a central office and eliminating repeated travel time while multiplying the effectiveness of each pilot on the team.

Percepto Air

Industrial-grade, weatherproof, and robust, Percepto’s DiaB offers autonomous visual inspections through the company’s autonomous drones, equipped with RGB and thermal cameras. Ready for 2D mapping, 3D modeling, volumetric measurements, construction monitoring, and more, the Percepto Air stands out due to its integration with Percepto AIM, an autonomous inspection & monitoring platform.

Combining visual data management and AI, AIM improves productivity and safety while minimizing risk and environmental impact. Designed with an open architecture, the platform is robot/sensor-agnostic, meaning that any drone, camera, or other sensors can integrate with it without new hardware. For example, in 2020, Percepto introduced a solution that combined Boston Dynamics’ Spot with Percepto AIM to redefine the role of autonomous robotics in large-scale industrial sites.

In late 2023, the FAA granted Percepto a nationwide waiver to operate up to 30 drone-in-a-box systems simultaneously with one single pilot.

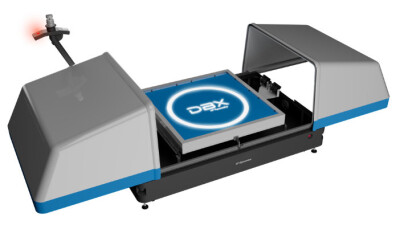

Hextronics

Built for various industries, including construction, Hextronics’ DiaB systems facilitate site surveying, progress tracking, and data-driven decision-making, ultimately expediting project timelines and ensuring greater accuracy. The company has developed a couple of DiaB over the years, and claims that its latest one, the Atlas, is “the world’s only portable DiaB battery-swapping platform”.

Built for various industries, including construction, Hextronics’ DiaB systems facilitate site surveying, progress tracking, and data-driven decision-making, ultimately expediting project timelines and ensuring greater accuracy. The company has developed a couple of DiaB over the years, and claims that its latest one, the Atlas, is “the world’s only portable DiaB battery-swapping platform”.

Compatible with the DJI M300 and various payloads, such as thermal cameras and lidar sensors, the Atlas’ main selling point is its quick, automatic battery-swapping capability. According to Hextronics, the use of their technology can increase productivity by up to 50% since the dock can switch out batteries in less than 6 minutes, allowing drones to return to the skies without any significant delays. To ensure minimal downtime, the dock can store up to eight batteries.

Furthermore, the Atlas features an AC cooling system, enabling it to operate in a wide range of temperatures and withstand harsh weather conditions. It is also built for portability, allowing it to be mountable on a truck, or carried by 3 people.

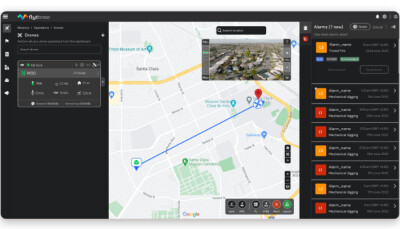

FlytBase DiaB Software Solution

While FlytBase’s DiaB software solution isn’t a docking station, it is a plug-and-play, hardware-agnostic solution compatible with all docking stations. DiaB users and manufacturers can easily pair FlytBase’s Edge Kit together with a DiaB system to gain access to the company’s complete software, and allow them to seamlessly automate complete workflows.

By leveraging FlytBase’s cloud platform, users have the flexibility to add unlimited drones and docks to the system, and then schedule missions and monitor them remotely through live stream HD multicam video over 4G/5G. In addition, the EdgeKit allows the drone to precisely maneuver and land on the docking station with high accuracy, as well as control the opening/closing of the dock, view telemetry, and turn on/off drone charging.

From perimeter patrolling and change detection to equipment monitoring and progress reporting, FlytBase claims to reduce operational costs; preemptively respond to incidents; enhance workflow efficiency; and increase safety & security in construction sites.

H3 Dynamics

Designed for mapping & surveying, inspections, construction monitoring, and more, H3 Dynamics’ DBX-G7 automates and digitizes visual inspection processes, creating an accessible layer of information on structures and buildings in any city. From the tallest skyscrapers to remote industrial outposts, the DBX provides an easy way to deploy scanner drones automatically, and remotely, at any time to refresh construction progress tracking reports.

According to H3’s partner SAP, H3’s solution speeds up building inspections, increasing productivity by 70% in some cases. “Our end-to-end report generation is much lower cost, and because we’re using AI and high-definition and thermal cameras, it typically finds 20% more defects than human-centered methods,” said Taras Wankewycz, founder, and CEO of H3 Dynamics. “Completion can be as fast as a couple of days – from data collection to analysis and report delivery, including official validation from a certified civil engineer.”

Featured as an open platform, the DBX is agnostic to drones, and payloads, and easily integrates with 3rd party AI/ML analytics solutions. It is already compatible with a large range of commercial drones, allowing end users to choose appropriate payloads and adapt to various applications. Also, the DBX is IP66 compliant and operates reliably, both on and off-grid.

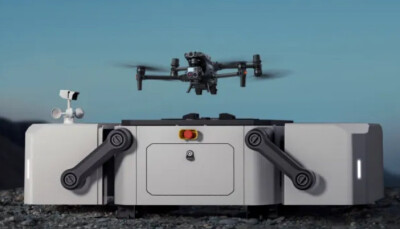

DJI Dock

Designed to facilitate remote and automated drone operations and to collect data on demand, the DJI Dock houses a DJI M30 or M30T drone and works in tandem with DJI FlightHub 2. Alternately, the Dock can be integrated with third-party software for flight planning and data management, such as FlytBase, or Drone Harmony. Heliguy, a UK drone company, claims that the M30’s range and flight time enable users to have “a regular eye in the sky on large-scale engineering and construction projects”.

The Dock features fast charging for minimal downtime (10% to 90% in 25 minutes), surge protection, and IP67 core components, making it weather-proof, and allowing it to operate at a temperature range between -35ºF to 122°F.

“It's a Swiss army knife for planning complicated complex 3D flights at your construction sites and difficult-to-reach places,” Martin Fuchsberger, Co-Founder and CEO at Drone Harmony, stated in a recent interview. “We also have automated obstacle avoidance in the flight planning engine, which makes it stand out and it's our unique selling point when you want to use it together with the DJI Dock.”

“I can see a situation where a drone in a box solution would be deployed on a job site at the beginning of the earth move,” added Richard Clement, Deputy General Manager at Komatsu. “This means during an activity where there's frequent earth-moving, a remote pilot can fly every day, and if then the activity drops off, they only need to fly weekly or bi-weekly. The DJI Dock gives you that flexibility, without being dependent on the availability of that person at the site to fly, map, and understand 100% of what's going on.”

Comments