This week is “Construction Safety Week,” an annual event that promotes the “industry’s safety culture and performance by strengthening the resolve of every person who walks onto a job site to be fully focused–mind and body–on safety.”

As most people know, construction work can be dangerous work. Heavy machinery and high-powered tools are always in use, and workers often find themselves in hazardous environments, such as on high scaffolding or in muddy ditches.

Working in these situations, construction personnel often fall victim to cuts and scrapes, strains, sprains, broken bones, and even electrocution. A round-up of recent studies on industry safety found that, each year in the US, 1% of construction workers suffer an injury serious enough to miss work. In 2022, the round-up reported, “there were 4.5 million medically consulted injuries among construction workers.”

Moreover, according to the US Bureau of Labor Statistics (BLS), construction is the second most dangerous profession in terms of fatalities. The agency stated that, “Workers in construction and extraction occupations had the second most fatalities (1,056) in 2022 compared to other occupation groups. Falls, slips, or trips were the events precipitating 423 of these fatalities.”

It’s no surprise, then, that the construction industry is focused on improving safety through initiatives like Construction Safety Week. It’s also no surprise that uncrewed systems are increasingly being put to use to bolster safety on job sites.

A recent article posted at For Construction Pros details the need for incorporating the technology. Drones, the piece reports, “are used on at least 37% of construction sites, and they can significantly reduce the need for human workers to climb to high areas for inspections. With falls from dangerous heights accounting for more than a third of fatal construction accidents, that’s a big deal.” Also, the story stated, there is “the potential for drone-mounted sensors to help detect heat signatures to prevent fires as well as dangerous equipment malfunctions, and in commercial spaces, robots are being used to detect slip-and-fall hazards.”

Calling for widespread adoption of uncrewed systems across the construction industry, the article said, “Automating high-risk activities is a huge net win for construction workers, who will increasingly be able to work remotely on dangerous tasks. Many injuries—sometimes fatal—can be traced back to human error, and the human element is one factor an automated system, working with precision and consistency, can completely eliminate. As long as a robotic system is configured correctly, it won’t make mistakes—and if something does go wrong, it will be replaceable equipment, not human workers.”

Here’s a look at a few ways the construction industry is turning to drones to enhance overall safety:

Safer Assessments of Historic Buildings

Older buildings can pose significant safety risks for construction workers. Materials degrade over time, and structures built during times of lax or even non-existent building codes can be hazardous places for workers. To help keep workers safe while inspecting older buildings, companies like Missouri’s Kuhn Construction are using drones. An article in Commercial UAV News chronicles how Kuhn deployed uncrewed systems to perform inspection work on old churches in St. Louis. “With a drone,” the article states, “the team doesn’t need to use ladders or lifts to get a bird's eye view. They can do all of that from the ground, which is critical for structures that have multiple roofs, which most churches do. They can also fly the drone inside the church to get to places that would otherwise be impossible or prohibitively expensive to access.” Moreover, drones can identify “places and structures were deemed to be unsafe, helping the parish contacts make decisions that avoided a potentially catastrophic situation.”

Drone with Ultrasound Reduces Risk

Traditional inspections often involve individuals physically climbing structures using ropes, scaffolding, or cranes. The new Skygauge Inspection Drone can be flown to perform site inspections, and it has the added ability of deploying ultrasound to monitor structures, which improves the efficiency, accuracy, and safety. According to Nikita Illiushkin, Chief Commercial Officer and Co-Founder at Skygauge, his company’s technology could save hundreds of lives per year and prevent thousands of injuries. “Using the Skygauge drone,” he asserted, “can drastically increase access to structures, make the work significantly faster and more cost effective, and keep workers safe.”

Drone-in-a-Box Solutions Improve Worksite Safety

A recent Commercial UAV News article explained how the construction industry has embraced the Drone-in-a-Box (DiaB) concept, which could “revolutionize how construction projects are monitored, surveyed, and managed from start to finish”—and lead to safety improvements. Among the highlighted systems were Percepto Air’s DiaB, which combines “visual data management and AI” to improve “productivity and safety while minimizing risk and environmental impact,” and the FlytBase DiaB software, “a plug-and-play, hardware-agnostic solution compatible with all docking stations” that can “reduce operational costs; preemptively respond to incidents; enhance workflow efficiency; and increase safety & security in construction sites.”

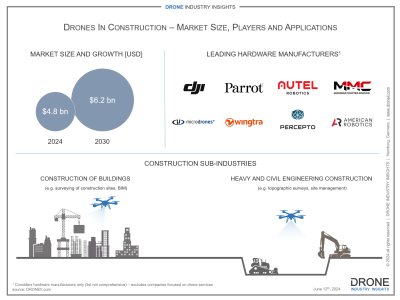

Want to learn more about the ways drones are improving operations in the construction industry? Download the Commercial UAV News Sector Snapshot: Drones in Construction.

Comments