Routine inspections and regular data collection are key components of maintaining smooth operations of any infrastructure. Traditionally, these tasks involve sending out inspection teams, which can be time-consuming and costly. With the arrival of Drone in a Box (DiaB) solutions, routine inspections have become faster, more accurate, and cost-effective.

After our DiaB solutions for Construction and Energy & Utilities articles, this last part will focus on some of the available solutions for Industrial Inspections and how they are helping companies to identify anomalies early, increase safety, and reduce downtime, as well as costs.

American Robotics’ Optimus System

On a mission to deliver strategic solutions that redefine the possibilities of drone operations, Ondas Holdings’ American Robotics developed the Optimus System to provide a fully automated, comprehensive solution for government, public safety, and critical infrastructure.

Designed for critical operations, the Optimus features a flight time of 40 minutes, a range between 5 to 10 miles, and holds up to 11 swappable batteries. Additionally, the dock can store up to 9 swappable payloads, making it a versatile tool for any mission, and uses edge computing to process data and provide insights in real time.

Last year, American Robotics signed an agreement with the Massachusetts Department of Transportation Aeronautics Division (MassDOT Aeronautics) for a 6-month fully funded initial engagement, serving as a notable step in the company’s strategy to introduce Urban Drone Infrastructure to government markets in the US. The agreement enabled American Robotics to showcase Optimus’ capabilities to improve data collection for enhanced safety and cost reduction in key areas such as rail inspections.

Also in 2023, the FAA granted the Optimus system a Type Certificate to streamline operational approvals for broad flight operations over people and infrastructure. In addition, American Robotics secured a BVLOS waiver for autonomous operations in Massachusetts through October 2027, allowing the Optimus to operate under realistic conditions in a fully remote and autonomous mode.

Avy

As an autonomous, remotely monitored, and easily deployed solution, Avy’s BVLOS Drone Response Network features the “only fixed-wing VTOL-from-a-box” and fast response times with low operational costs for inspections and more.

Compatible with multiple payloads, Avys’ drone, the Avy Aera, is a VTOL fixed-wing drone that withstands winds of up to 30+ knots, and flies in “heavy rain and harsh sunshine, in blistering cold or sweltering heat”. The Aera includes an onboard parachute for safe urban deployment, ensuring that even in the case of a full loss of power, a bird strike, or any other major incident, people on the ground will be safe.

In 2021, Avy used its DiaB solution to provide harbor masters’ operational teams at the Port of Rotterdam with high-quality imagery of areas of interest, such as infrastructure and environmental inspections and monitoring. In 2022, the company started testing BVLOS flights, and, by 2023, it had flown around 620 BVLOS miles across 3 different routes, covering the majority of the port. Future developments include the integration of Avy’s dock with the existing camera network in the Port of Rotterdam, and the start of remotely operated flights to further improve the safety and efficiency of port operations.

Sphere Drones’ HubX

As an all-terrain, solar-powered, and internet-enabled solution, Sphere Drones’ HubX isn’t your typical DiaB. It is a mobile and portable system that comprises three main components:

- A solar trailer to support continuous and uninterrupted self-sustaining drone operations.

- The WatchTower to enable BVLOS flights anywhere, including rural remote environments.

- A DJI Dock with a DJI Matrice 30T.

Suited for several use cases, including critical or remote assets inspections, the HubX provides automated data capture and streamlines repetitive and resource-heavy surveying tasks from site to office. Users can subscribe to Sphere Drones’ Curo software to process collected data or integrate the HubX with existing drone management software via an API. To make sure the drone is always connected to the dock, the company integrated Elsight’s (ELS) connection confidence Halo technology, allowing HubX to have multiple connections and redundancy to the internet.

In November 2023, Optus, a major Australian telecommunications company, had a sudden network outage that lasted 13 hours. During that time, Sphere Drones was using the HubX at a mining site while performing BVLOS flights, where it’s critical to always have a connection to the drone. The HubX was connected to the internet via two Optus and two Telstra SIM cards with a satellite connection via Starlink. As soon as ELS’ Halo device detected the outage’s network degradation, it automatically switched the main connection to allow HubX to continue operating unaffected.

“HubX includes everything you need to roll out a BVLOS operation,” said Sphere Drones’ CEO Paris Cockinos. “The portable device has the potential to help businesses meet their daily operational requirements.”

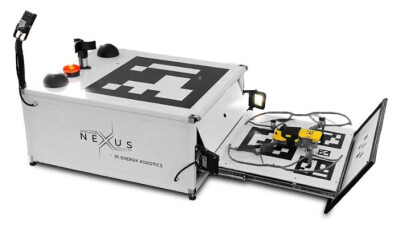

Energy Robotics

On a mission to relieve humans from dangerous, repetitive, and undesirable tasks, Energy Robotics developed an end-to-end solution for autonomous inspections in capital-intensive industries such as oil & gas, chemical, as well as power and utilities. The company’s hardware-agnostic software platform enables other companies to easily manage a fleet of robots and drones for autonomous inspection.

BVLOS approved in both Germany and the European Union, Energy Robotics’ platform integrates seamlessly with different docking stations. This combination allows users to remotely execute automated drone inspections and supervise drone flights effortlessly, all through a simple browser interface.

Using Energy Robotics’ platform with two different ground robots and a drone, Shell has implemented 360° automated inspection from the ground and the air at the Shell Energy and Chemicals Park Rheinland. By equipping the different robot types and the drone with visual and thermal cameras and other special sensors, Shell collects pressure and temperature readings with artificial intelligence and computer vision. Moreover, the robot team records and analyzes valve positions or objects, such as fire extinguishers, collects thermal images of insulation and machines to detect thermal anomalies, and registers small quantities of escaping gases in the ppm range.

"We are proud to have put a mixed fleet of autonomous inspection robots and a drone into operation as part of our innovation and digitalization efforts,” explained Thomas Klein, Digital Innovation Lead at Shell Energy and Chemicals Park Rheinland. “The different specifications of the individual models give us the flexibility we need to inspect a large number of inspection points automatically.”

Skydio Dock

As already mentioned in our first article of this series, the Skydio Dock is one of the more advanced, smallest, and lightest docks available, allowing companies to perform continuous remote monitoring and inspections in many different environments.

By pairing the Dock with the Skydio X10 drone, users can easily obtain “limitless visibility and automate site inspections” without the need for a human on-site or in the loop. On top of the Dock’s advantages, the X10 can be a game changer for drone inspections with its Onboard Modeling feature. This feature enables the X10 to create 3D models and 2D maps on the drone itself, eliminating the need for additional photogrammetry software, external systems, or even internet connectivity. This means that inspectors can process textured 3D models on-site, validating the quality of completed scans almost in real time. Not only does this save time and resources, but also minimizes the need for revisiting sites, reducing costs, and increasing efficiency.

Recently, Skydio partnered with Mitsubishi Electric Power Products, Inc. (MEPPI) to “redefine the landscape of substation inspections and maintenance”. The collaboration combines Skydio’s autonomous drone technology, including the company’s docks, with MEPPI’s Power-I. The Power-I is a computer-vision-based analytics platform that automatically ingests visual data, detects and digitizes components using AI created specifically for utility assets, creates operational baselines, detects anomalies, and reports on a wide range of events in real time through customizable alerts. The integration of MEPPI’s platform with Skydio’s drones and docks turns substation inspection workflows significantly more streamlined and efficient. After executing an autonomous mission using a Skydio Dock, the data is uploaded to Skydio Cloud, and Power-I automatically reads that data to run AI analysis and identify any anomalies.

"By integrating our advanced drones with MEPPI's Power-I system, we're not just elevating the efficiency and accuracy of data collection; we're setting a new standard for operational excellence in the utility industry,” commented Christina Park, Senior Director of Energy Strategy at Skydio. “Our drone solutions, renowned for their autonomous capabilities and EMI resistance, complement Power-I's analytics to offer an unparalleled solution that promises to enhance the reliability and performance of our aging electric grid. Together, we're not just facing the challenges of increased grid stress; we're pioneering a future where inspections are safer, faster, and more reliable."

Comments