Italian drone provider Italdron manufactures and markets drones for various professional applications, including surveying, mapping, and inspection work. RTK technology enables the capture of high-precision data necessary for such tasks. High safety and reliability standards guarantee that the drones perform well under challenging circumstances.

Italdron was founded in 2008 when founding partner Luciano Morigi realized the potential of remotely piloted aircraft systems in civilian applications. In 2016, Italdron opened its Drone Academy offering comprehensive training programs for individuals aspiring to become professional Remote Piloted Aircraft Systems (RPAS) pilots. Today, the Academy has more than 20 training sites across Italy.

The company invests in continuous research and development through an in-house R&D laboratory. Another innovative feature is the use of 3D printing: since 2014, Italdron has been using WASP’s 3D printing systems for prototyping and the production of final drone components. These not only help reduce development times and costs but also enable customizing a drone to meet specific customer needs.

Italdron was also the first Italian manufacturer approved for “post-production flights,” which means it is licensed to perform flight testing of its drones after manufacturing and validating the functionality of sensors, cameras, and control systems. This certification shows Italdron not only focuses on building advanced drones but also on maintaining high standards of safety and reliability.

Italdron was also the first Italian manufacturer approved for “post-production flights,” which means it is licensed to perform flight testing of its drones after manufacturing and validating the functionality of sensors, cameras, and control systems. This certification shows Italdron not only focuses on building advanced drones but also on maintaining high standards of safety and reliability.

UAVs for mapping, surveying, and inspection tasks

Italdron offers multiple drones for mapping, surveying, and inspection tasks. For example, the Agrodrone and TitanXLE are both highly modular drones that support varied rotor configurations. Released in 2017, the TitanXLE offers a flight time of up to one hour with a 1kg payload and operates silently at 150 meters altitude. This feature is advantageous in urban or noise-sensitive areas where traditional survey equipment might disrupt the surroundings. The drone has been optimized for survey-grade imaging and carries photogrammetry cameras or LiDAR scanners.

The Titan 4HSE is a quadcopter, primarily used for medium-payload applications like aerial inspections, photogrammetry, and surveying. It features a maximum takeoff weight of 5.5 kg and flight autonomy ranging from 15 to 30 minutes, depending on the payload. One notable feature is the flight planning software which includes tools for executing grid and surveying missions, facilitating georeferenced aerial photogrammetry. Other applications include aerial inspections and search and rescue operations.

RTK capabilities for high-precision data

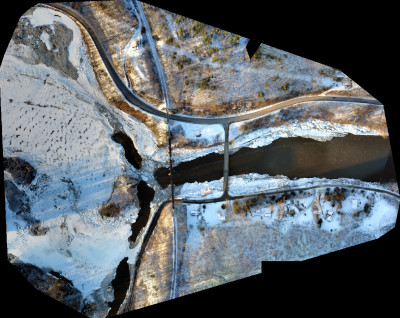

Italdron’s Titan 4HSE, TitanXLE, and Scrabble 6HSE are all equipped with RTK (Real-Time Kinematic) capabilities, designed to deliver high-precision data for surveying and mapping projects. By measuring the phase of satellite signals and utilizing a reference station for real-time corrections, RTK achieves positioning accuracy within approximately 10 centimeters. This precision is suitable for high-accuracy GIS mapping and detailed 3D modeling. Integrating RTK systems into drones enables precise aerial operations in challenging environments like landslides, where on-site presence is hazardous.

Thermal monitoring in Abu Dhabi

The Titan 4HSE was used in a thermal monitoring project in Abu Dhabi. In collaboration with Abu Dhabi's Technometer company, Italdron conducted thermographic monitoring of the large stained-glass windows on Abu Dhabi's skyscrapers. The team faced challenges such as flying at 45°C with 75% humidity and maintaining a constant distance of 10 meters from a 300-meter-high skyscraper. The mission involved surveying the five towers of the Etihad Towers complex, located near the Emirates Palace and the Presidential Palace. Over two days, more than 40 flights were completed, collecting extensive data. The combination of a radiometric camera and a visible camera on the drone provided significant results, saving technicians considerable time and reducing risks associated with manual data capture.

Detecting methane leaks with drone technology

Amber Grid, Lithuania's gas transmission system operator, has partnered with Italian manufacturer Italdron to develop and test innovative drones capable of detecting methane leaks. These drones enhance the safety and reliability of the gas network by efficiently monitoring and controlling methane and CO₂ emissions, thereby protecting the environment, flora, and fauna along the pipelines.

Technical Director Andrius Dagys emphasized that such innovations enable more efficient pipeline inspections with reduced CO₂ footprints. Traditionally, Amber Grid inspected its 2,000 km of pipelines using helicopters equipped with laser detection and manual devices. The new drone technology is expected to achieve environmental and reliability goals more effectively. The system comprises two drones: a primary drone that follows a set route over the pipeline to detect gas leaks and a secondary drone that inspects and records the exact location of any detected leaks.

Comments