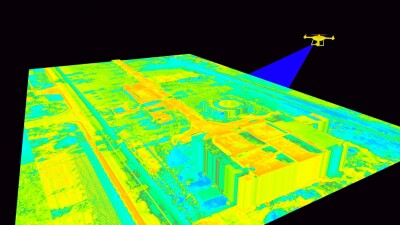

Demand on our energy utilities are ever-increasing as urbanization accelerates, our infrastructure ages, and climate change causes greater need for heating and cooling in extreme temperatures. Combined with worker shortages across industries, the need for technology to fill these gaps and ensure consistent inspection and maintenance is crucial. Among the technologies being leveraged for these is drones with lidar and RGB payloads, which are then used to create digital twins of assets.

Commercial UAV News caught up with Kristy McDermott, Vice President of Global Sales & Commercial Processes with Sharper Shape. The company, founded in 2013, provides the software to take the data from aerial capture – using both crewed or uncrewed aircraft – to create these “living digital twins.”

McDermott explained that their users, who are generally investor-owned utilities, use the software for asset and vegetation management. There are a variety of uses on the asset management side, though she notes that the majority is for conflation of their assets. In other words, these digital twins give accurate location information for the assets along with “a full inventory of what’s on their distribution and transmission structures.”

The other major use case by these utility owners is vegetation management, monitoring vegetation encroachment on their assets. This can mean fall-in trees, urgent issues close to phase-wires, and overhang branching issues.

The newest release that Sharper Shape was showcasing at this year’s event is their Asset Insights, which leverages artificial intelligence to automate much of the analysis of these digital twins. Given the aforementioned worker shortages combined with high demand, this kind of automated detection is a massive boon for these owners.

The tool has two main applications with component identification and defect detection. For the former, many utility owners don’t have a full inventory of all of their asset components, but this tool will automatically detect and classify components from the model, all of which are georeferenced. Defect detection, meanwhile, will find specific assets and components that may need work to ensure workers are being sent to the most important areas first. The tool will give percentage certainties for each detection that maintenance is required.

Utility owners are very much in need of these automated, sensor-agnostic tools to keep up with demand. As artificial intelligence continues to improve, companies like Sharper Shape are leveraging the technology for specific, crucial workflows in the utilities industry.

Comments