Let's be honest. When people think of working in the fields of surveying and inspection, they often think of climbing over machinery or figuring out how to use a stationary total station. But the rise in the use of 3D mobile mapping platforms has made that easier and more robust.

Central to these improvements is the use of lidar-based autonomous drones that can explore areas too dangerous for people to go. Best of all, operators don't have to be drone or SLAM experts to get the job done. The tech makes the work easier and more approachable.

A recent collaboration between Exyn Technologies and Canada-based Dundee Precious Metals (DPM) shows how this technology can also change the ways that we do the work. Sure, using an autonomous drone in a mining environment was weird at first. But now their entire cavity monitoring workflow revolves around the use of the drone. Their surveyors are trained to prep newly blasted areas underground for immediate mapping with their UAV. And they've even adjusted the underground environment to ensure the best performance from the drone.

A recent collaboration between Exyn Technologies and Canada-based Dundee Precious Metals (DPM) shows how this technology can also change the ways that we do the work. Sure, using an autonomous drone in a mining environment was weird at first. But now their entire cavity monitoring workflow revolves around the use of the drone. Their surveyors are trained to prep newly blasted areas underground for immediate mapping with their UAV. And they've even adjusted the underground environment to ensure the best performance from the drone.

A Symbiotic Partnership for Continuous Improvement

In 2018, DPM needed to make a substantial investment to modernize the Chelopech gold-copper mine in Bulgaria, which prompted the team to seek out cutting-edge innovation partners. An industry summit in Canada forged a partnership with the innovative American start-up Exyn Technologies, a company at the forefront of industrial drone and robotics technology.

The Dundee team saw potential in Exyn’s work and entered into a collaboration. In the process, Dundee’s surveyors developed a greater understanding of robotics and autonomy, and the Exyn team gained crucial knowledge about the mining workflow and mine safety. The result of the joint efforts was a symbiotic partnership that deployed the self-navigating ExynAero autonomous drone below the surface in an environment devoid of GPS, i.e., without signals from satellites, orienting itself to the empty spaces (stopes) it needs to scan in some of the most complex mines in the world, including in Chelopech.

Exyn proved to be the right company to enable Dundee Precious Metals to succeed in improving safety and efficiency for surveyors on the basis of value, as well as engaging people who love their professions and strive for continuous improvement.

Enhancing Safety, Speed, and Accuracy

Enhancing Safety, Speed, and Accuracy

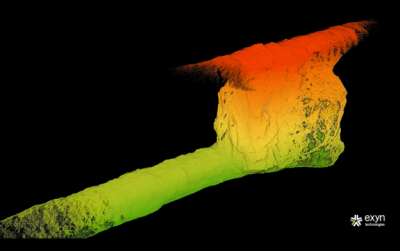

Introducing Exyn’s autonomous drone in the Chelopech mine has increased safety by reducing surveyors' time underground, thanks to its lightning-fast scanning. Also, the data obtained from the drone is extremely accurate, providing 20 million points scanned over a couple of minutes. The detailed image, covering every single corner, makes it much easier for technical personnel to analyze and work. By comparison, before the Exyn drone, surveyors used CMS that had about 50,000 points scanned over a much longer period of time. Using its data-driven analysis, Exyn autonomous robots not only enhance scanning, safety, and speed but also ensure accurate mine blasting, optimal ore extraction, and reduce unnecessary costs by preventing the sterilization of rock mass.

Autonomous Drones, 3D SLAM Mappers, and Digital Twins

The success of the Exyn-DPM collaboration shows why autonomous drones and 3D SLAM mappers have become more widely used in surveying and inspection operations. Obviously, underground mining takes place in complex environments and that draws increased attention to the safety of personnel and equipment. Using robotic technology allows real time mapping and analyses of previously unreachable locations and raises the bar for responsible miners.

The ability to collect vast amounts of data in just one drone flight is a significant achievement that has proven its weight in gold for the surveyors of Chelopech in terms of safety, quality, and speed. Enabling the drone to navigate in an environment they have no prior knowledge of saves money, time, and trouble. What makes 3D SLAM mappers ideal is that the sophisticated computational technique they use enables the self-directed drones to chart out unfamiliar environments while keeping track of their location.

Also, Exyn’s SLAM pipeline enables the robot to autonomously navigate many extreme field conditions, including GPS- and comms-denied environments with little to no light, communications with a pilot, or existing infrastructure.

In addition, the improvements at Chelopech point to the benefits of technologies like digital twins. The creation of comprehensive digital representations of different environments helps professionals solve complex tasks while minimizing the risk of mistakes. And what is most important is that it revolutionizes the speed of decision making.

Despite these successes, the Exyn-DPM collaboration shows that staying current with autonomous technology, 3D SLAM mappers, and digital twins is no longer enough. Challenging existing knowledge and expanding technology boundaries is becoming more important for companies that want to stay competitive, increase efficiency, and innovate the industry.

People, Knowledge, and Technology

People, Knowledge, and Technology

The Chelopech mine collaboration showcases how Dundee Precious Metals owes its success to its people who love their profession and strive for continuous improvement. The company invests in the knowledge of its employees, helps them further develop their skills and experience. Thanks to the innovative spirit of Chelopech mine surveyors and the need to expand knowledge and technology combined with the professionalism of Exyn, the drone has been in operation since 2018 and evolving. Other mining companies who can draw valuable experience from Dundee Precious Metals Chelopech are also interested in the product.

Further, what makes Exyn not only a visionary partner but also a trusted collaborator is the company’s ability to work along with their clients and not only provide training but also allow them to get trained. Taking innovation at heart is what makes it possible for Exyn and Dundee Precious Metals specialists to test ideas and go beyond just one industry.

Looking to the Future

As the work at Chelopech shows, not only does the deployment of bleeding-edge tech make today's work easier for your average surveying or inspection team—it is also crucial in enticing a younger generation to pursue careers in the field. Showing off that your surveyors and inspectors are using autonomous robots gives you a competitive advantage for customers and potential employees. As we continue to digitize the world around us, businesses can quickly fall behind if they're not cultivating a workforce capable of rapidly capturing and processing digital twins of ongoing operations.

Many young people interested in careers that involve autonomous robots, AI, and related technologies might not first think of the mining industry. However, being able to use interactive drones, develop practical applications, and quickly get results that evaluate the quality of an operation are characteristics that appeal to young people. It is ever more necessary for young people that strive for good careers to possess the skills to transpose virtual into real life experience—and the success of the Exyn-DPM operation at Chelopech show how those skills and experiences can come together in a rewarding way.

Comments