An American Invention Inspired by Customer Needs and Ingenuity

Anyone who’s driven by a construction or similar worksite has likely noticed that pickup trucks are predominant, both as work vehicles and as the favored personal transportation for those who work there. What is behind this phenomenon and what can drone manufacturers learn from it? A century ago, American automobile pioneer Henry Ford noted that many farmers were altering their Model Ts to serve as work vehicles. From this, the 1925 Model T Roadster, the first pickup truck was born.[i]

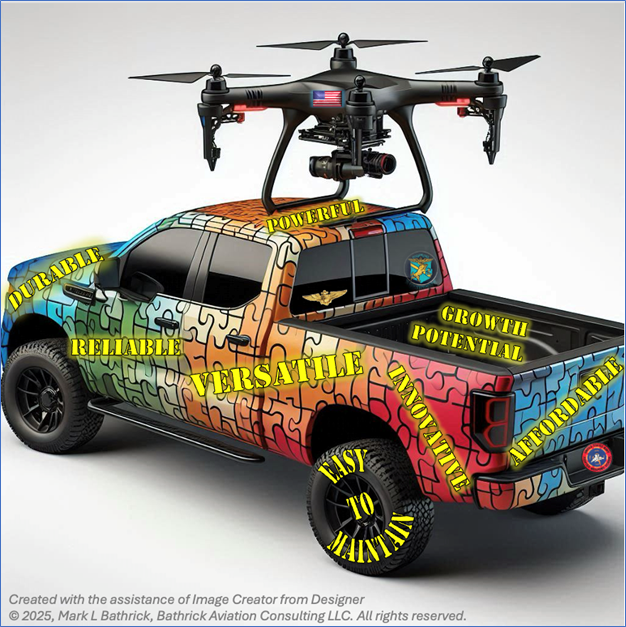

Pickup trucks are built to endure the rugged conditions often associated with worksites. They are designed with reliability, ease of operation, and field-capable maintenance in mind. Those who buy them know that breaking down or having a key piece of technology go inoperable at a remote worksite can be costly in multiple ways.

Beyond their durability, pickup trucks offer exceptional versatility. They can accommodate a wide range of payload shapes, sizes, and weights in the truck bed. The introduction of the “crew cab” further enhanced their versatility, enabling them to transport entire work teams or families. Moreover, the convenient trailer hitch allows for the attachment of an equally diverse array of “payloads,” making pickup trucks the primary vehicle found at worksites and the preferred personal choice for many workers in these locations.

There is no vehicle more American than the pickup truck. They have consistently been one of the most popular vehicle types sold in the U.S. This enduring popularity is evident in the data from the first nine months of 2023, where American pickup truck brands dominated the sales charts, solidifying their position as the top three selling cars,[ii] a trend continues today.[iii] While retaining the ruggedness, dependability, and versatility that made them a perennial favorite, the American pickup truck has continued to evolve, offering new innovations in response to growing customer needs and expanding use cases.[iv] These attributes were the driving force behind my decision to purchase a Ford Super Duty 4X4 in 1999, which became my trusted “workhorse” for an impressive 21 years. I am grateful for the versatility of this vehicle, which I consistently leveraged throughout those two decades.

The American Pickup Truck Inspires a Drone Program

In 2006, when we began designing the U.S. Department of the Interior’s (DOI) “Drones for Good” program, the American pickup truck served to inform our drone selection strategy. We were acutely aware of the scope of departmental responsibilities and use cases we believed drones could help us with. As the designated steward of approximately 20% of America’s land mass (~500 million acres), DOI’s responsibilities were vast.[v] The number of mission types that must be accomplished to fulfill these obligations to the public and the nation is both extensive and varied.[vi]

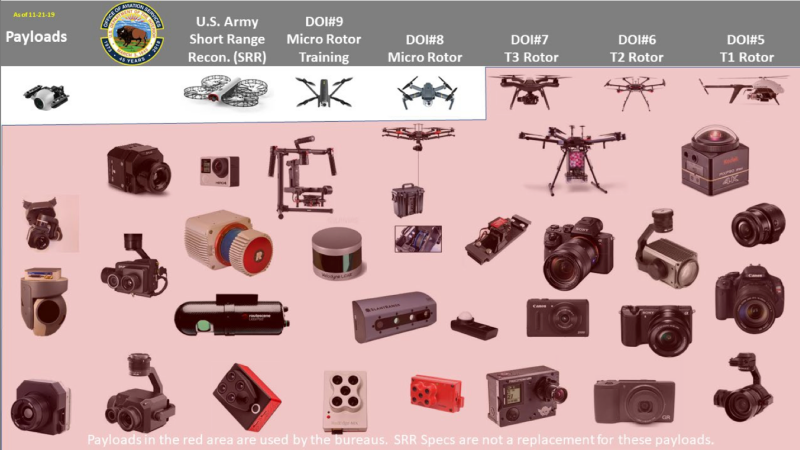

Our drone program also had to live within the fiscal constraints of DOI appropriation. Having just retired from the military, it was a bit of a shock to learn that despite DOI’s vast stewardship responsibilities, its annual appropriation level represented only about 2% of what DOD received annually (FY25, DOI = $18B; DOD = $842B).[vii] [viii] Clearly, the “Drones for Good” program we envisioned for DOI could not be built on the same DOD model I had become accustomed to in my military career. However, knowing the military often excessed serviceable assets to make way for new and improved versions, we first leveraged that program to facilitate our initial operational test and evaluation (OT&E) of drones as a new tool for DOI. In 2008 we received dozens of excess DOD small UAS (Raven A/B, T-Hawk) at no cost and flew them on hundreds of DOI mission flights over a five-year OT&E program.[ix] Although our hope was that we could take advantage of a steady stream of excessed military drones to sustain our drone fleet into the future, we learned during OT&E that the DOD UAS were highly specialized with fixed sensor payloads that often did not meet DOI bureau requirements for sensor resolution and versatility.[x] We also learned these UAS were expensive to modify and maintain and required extensive training.

Unable to find a versatile and affordable military drone that met DOI’s mission needs and funding constraints, we looked to the commercial sector for a “pickup truck” drone platform for our nascent DOI drone fleet. After extensive market research, the “pickup truck” we first chose in August 2016 was the Solo quadcopter, built by 3D Robotics of Berkeley California.[xi] Although originally sold with only a detachable GoPro camera, like the farmers of 1925 who saw the untapped potential in their Model T’s to meet their unique needs, we recognized the Solo’s capacity to carry the wide array of payloads necessary to support the extensive requirements of DOI bureau missions.

Through a deliberative research, development, test, and evaluation (RDT&E) process patterned on those taught at military test pilot schools, we quickly, safely, and effectively responded to requests from field users for additional mission-essential payloads, eventually qualifying 12 different ones for the 3DR Solo.[xii] [xiii] In those cases where the bureau requested sensor mount was incompatible with the standard 3DR Solo attachment

hardware, a 3-D printed interface was derived and used. Although the first contract was for only 50 3DR Solo aircraft, bureau user demand for this rugged, affordable, adaptable, and easy to maintain “pickup truck” resulted in the Solo becoming the predominant aircraft in the DOI UAS fleet, peaking at 480 aircraft and comprising 56% of the DOI UAS fleet inventory in January 2021.[xiv]

Sample DOI UAS mission applications performed by the 3DR Solo “pickup truck” included:

1. Spot fire detection & guiding to firefighters to extinguish them.[xv]

2. Three-dimensional modeling of large geographic features for climber risk mitigation.[xvi]

3. Geologic hazard analysis and rockfall mitigation.[xvii]

4. Volcano monitoring.[xviii]

5. Archeological site surveys.[xix]

6. Topographical surveys.[xx]

7. Dam inspections.[xxi]

8. Photogrammetric mapping.[xxii]

9. Multispectral mapping.[xxiii]

10. Wildfire mapping.[xxiv]

11. Search and Rescue.[xxv]

12. Surface mine surveys.[xxvi]

13. Physical safety inventory updates.[xxvii]

The Quest for Bigger, “Badder” Payloads

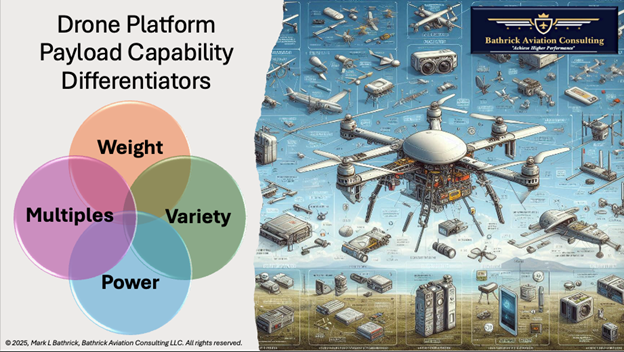

There’s a common attribute among all aircraft as they proceed through their lifespan and drones are no different. As users gain experience and mission success with aircraft, they look to expand what they can do with them, which often results in wanting to add more capabilities to them, resulting in increasing payload weight, versatility, and power requirements. This was certainly true with the military aircraft I flew, like the F-14.[xxviii] During its lifespan, numerous systems and weapons upgrades were incorporated that increased its mission capability, but also its weight. Similarly, the success DOI achieved with the 3DR Solo, resulted in increasing bureau demand for even more capable “pickup truck” drones, with the capability to carry:

- Heavy weight payloads.[xxix]

- Multiple payloads at the same time.[xxx]

- A wider variety of payloads, including those that could:

- High power demand payloads (e.g. advanced industrial tools, robotic payloads, AI-driven systems, directed energy systems, electronic warfare modules, etc.).[xxxv]

Together, these “light” and “heavy” duty drone pickup trucks helped DOI save an estimated $14.8M and $15.9M in operations costs in 2018 and 2019 respectively.[xxxvi] [xxxvii]

DOI’s story of leveraging “pickup truck” drones to achieve quick, cost-effective, agile and meaningful success is not alone. The U.S. Department of Agriculture’s (USDA) U.S. Forest Service (USFS) faced similar responsibilities and funding levels, leading them to adopt the same approach. Consequently, they have been a close partner with the DOI’s “Drones for Good” program since the initiation of their Unmanned Aerial System (UAS) program in 2014.

However, Ukraine stands out as the undisputed leader in drone innovation by transforming conventional drones into multipurpose "pickup trucks" of the sky—flexible, robust platforms that rapidly adapt to the dynamic battlefield.[xxxviii] Ukrainian engineers have ingeniously repurposed commercial drones into modular systems capable of not only precision strikes but also real-time intelligence gathering, payload delivery, and even decoy operations that disrupt enemy logistics.[xxxix] This evolution stems from a relentless spirit of innovation under extreme conditions, where necessity spurred the creation of lightweight, cost-effective, and easily reconfigurable drones that confound traditional air defense systems. Their ability to integrate commercially available technology with military-grade functionality has not only maximized operational flexibility on the ground but also attracted substantial international interest from Western defense industries, solidifying Ukraine’s reputation as a global leader in drone innovation.

Pickup Truck Lessons for Drone Manufacturers

Drone manufacturers, particularly those in America have faced numerous significant challenges in this rapidly evolving industry.[xl] The stringent U.S. regulatory environment, particularly regarding beyond visual line-of-sight (BVLOS) operations and easy flight certification for drones weighing more than 55 lbs. has hindered commercial scalability and limited innovation.[xli] [xlii] However, recent U.S. government statements regarding plans to review and streamline regulatory processes and approvals provides some hope for manufacturers, investors, and customers.[xliii]

U.S. drone manufacturers have long faced intense competition from foreign drone manufacturers. Unfortunately, policy and legislative efforts aimed at addressing this competition by restricting the purchase of foreign drones have not yielded the desired outcomes.[xliv] As a result, cost increases, supply chain issues, and uncertainty surrounding acceptable drone designs have led to lower-than-expected customer demand, reduced outside investment, and declines in new product research and development. Moreover, drones from some of the largest U.S. drone manufacturers come equipped with stock sensor payloads that cannot be easily interchanged or upgraded over time. This design philosophy runs counter to growing customer demands for a "pickup truck" drone—a versatile platform in which sensor modules can be swapped out like interchangeable tools to meet a variety of operational needs. These rigid and expensive offerings pose particular challenges for government agencies and smaller enterprise customers, who find themselves justifying more expensive drones that resemble niche “sports cars” rather than the “pickup trucks” that can easily adapt to emerging technologies and broad mission requirements. This lack of modularity has hindered U.S. firms from securing the market share enjoyed by more adaptable competitors, as clients increasingly favor platforms that promise longevity, flexibility, and cost-effective evolution in their capabilities. While there are some notable “pickup truck” drone exceptions among American drone manufacturers, they constitute a minority. Drone manufacturers must recognize that the tasks and missions performed by drones were accomplished before their existence, albeit not as safely, efficiently, or effectively. When the U.S. drones available to customers become excessively expensive and resemble “rigid tools in a highly dynamic world,” those customers may revert to traditional methods used to accomplish those tasks and missions before the advent of drones. This scenario would not serve the U.S. drone industry nor its U.S. customers well.

The “Pickup Truck” Drone, a Competitive Opportunity for American Drone Manufacturers

The American pickup truck, a rugged and versatile tool that has stood the test of time, was first conceived a century ago.[xlv] Its enduring popularity can be attributed to the ingenuity of Americans who continuously modified and improved existing products to meet their growing needs. Today, pickup trucks have evolved to meet the current and future needs of their customers, with features such as electric and hybrid powertrains, multi-function tailgates, offroad capabilities, integrated storage solutions, connectivity, smart features, auxiliary power delivery capabilities, and increased payload and passenger capacities.

The story of the DOI “Drones for Good” program and the achievements of Ukrainian drone manufacturers provide valuable examples of how American drone manufacturers can gain relevance in the highly competitive drone market. While challenges remain outside the direct control of American drone manufacturers, the lessons learned from the 100-year history of American innovation and success exemplified by the pickup truck offer an opportunity to reclaim American leadership in this critical technology.

It’s important to remember that Henry Ford didn’t invent the American pickup truck; it was the American farmers he observed modifying his Model T and listened to understand their needs that inspired him to create this enduring innovation that has led the world market for a century.[xlvi] Drone manufacturers can draw inspiration from this American legacy by actively listening to and observing their customers and providing them with rugged, reliable, durable, versatile, and affordable “pickup truck” drones that cater to the ever-expanding range of use cases.

Comments