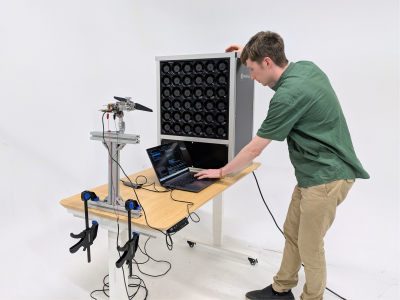

Tyto Robotics, based in Gatineau, Quebec, was founded to address the problem of inefficient drone propulsion. By creating a thrust stand that accurately measures propeller thrust and torque, the company’s founders significantly improved propulsion systems, resulting in doubled flight times. This innovation spurred the development of their professional testing tools for motors, engines, propellers, and drones.

Today, Tyto Robotics has test equipment and software that has been designed to precisely measure thrust, torque, RPM, power and efficiency to help drone designers optimize their propulsion systems. At XPONENTIAL Europe, the Tyto Robotics team was on hand to highlight their wide range of professional testing tools for all sizes of UAVs as well as their new, “Propeller Balancing to Enhance UAV Performance and Service Life” whitepaper. This new resource explores the causes, consequences, and solutions for UAV propeller imbalance.

Charles Blouin, Co-Founder and CEO at Tyto Robotics presented at the event to outline these specifics to attendees. He explained the effects of propeller imbalance in UAVs and how dynamic propeller balancing provides a practical and effective solution to mitigate these risks. He also highlighted how these efforts would improve operational efficiencies and reduce costs for commercial operators and operations.

“It’s really about having a deeper understanding of the tools,” said Charles Blouin, Co-Founder and CEO at Tyto Robotics. “UAV propeller imbalance isn’t just about inefficiency, as it also impacts airborne reliability. By regularly balancing propellers, you'll see increased efficiency today and ensure your UAV remains safe and reliable for years to come.”

You can see how it works via the link below...

As the video showcases, achieving ISO grade results in possible in just three easy steps. Such efforts can enable UAV systems to operate at peak efficiency, ensuring greater reliability, lower noise emissions, and an extended service life.

To learn more about propeller balancing tools and techniques, visit the Tyto Robotics site.

Comments