Flight time. It’s the biggest problem facing the drone industry. And, as BVLOS becomes more widespread in the near future, flight time is only going to become more critical. You can of course get a drone with long flight time but the cost is out of reach for most drone operators.

And drone operators are desperate for a solution.

Matt Koball is CEO of Dropcopter, a company that built a proprietary pollen distribution module that attaches to drones and that provides pollination services to farmers for their fruit and nut trees and other pollinating crops.

“We’re pollinating hundreds of acres and in some cases even in the thousands of acres. There is a small window of time to do it so we need to be fast—and that is a logistics challenge,” said Matt. “A challenge that is made even more difficult with our current fleet of drones. We barely get 15 minutes of flight time. So that means we’re constantly bringing the drone back and forth swapping batteries. And like every drone operator, we’re only making money when the drone is in the air.”

Matt continues, “We’d love to have a drone with much longer flight time and we found one, but it cost $50,000. That level of cost just doesn’t make sense for us. It would make the cost to our customers, the farmers, far too expensive.”

Dustin from M3 Agriculture Technologies echoes this sentiment. M3 has developed what is called a “Sterile Insect Technique” or “SIT” technology and distribution system using drones. What’s SIT?

Dustin explains, “The sterilized insects mate with the wild insects but produce no offspring. This radically lowers the number of wild insects but with no insecticides. It’s way better for the environment and it is far more effective. Everyone wins.”

Yet, even though the benefits are huge, SIT hasn’t penetrated the agriculture market that much.

Dustin further explains, “SIT has been around for a long time but no one has gotten it to work efficiently, both from a manufacturing side and a distribution side. Everyone was trying to use airplanes but those are expensive, and it turns out that you either kill the insects or they don’t land in the fields where you need them. We’ve revolutionized all of this. Dramatically lowering cost and making SIT way more effective.”

But drones have been a weak point in M3’s otherwise revolutionary technology and model.

“We actually build all of our own custom drones because we couldn’t find anything on the market that worked for us. Each drone is still very expensive and our flight time is very low. About 15 minutes with a payload. And because flight time is low, we need to keep a large stockpile of batteries and a dedicated room in our office to charge all of them. That’s another huge expense we’d love to get rid of too.”

Eno Umoh, CEO of Global Air, explains: “It’s all about flight time. We work with 100s of drone operators to help them make their businesses grow and be more profitable and flight time is a constant issue. For example, we were just working with a client that has a building inspection service. With their drones they need to constantly disengage from the building inspection, bring the drone back, swap out the batteries, and then fly the drone back to the building. That takes time. I figure for each hour that client is doing the inspection, a full 20 minutes are spent on the battery swap. That’s kind of nuts when you think about it. This client is losing a lot of money, 33% of each dollar earned essentially.”

Patrick Walsh, CEO of EagleHawk, a premiere and rapidly expanding building and infrastructure inspection company, explains, “Because of the new set of laws and regulations limiting the use of certain drones for government entities, we’ve been shut out of providing services for certain customers. The problem is that there are almost no options in the market that have the right capabilities at price point that makes sense for us.”

These were the kind of end-user stories that Erik and Justin of Modovolo had heard more times than they could count and that was the kind of problem that they knew they had to tackle. But they knew that the standard fixed-hub design of drones wouldn’t work.

“We believe short flight time is because of the limitations of the current fixed-hub design. Everyone is taking the same approach. They are all trying to optimize the same tired, fixed design that’s been around since the dawn of drones.”

“We believe short flight time is because of the limitations of the current fixed-hub design. Everyone is taking the same approach. They are all trying to optimize the same tired, fixed design that’s been around since the dawn of drones.”

That’s why they created the Lift from Modovolo.

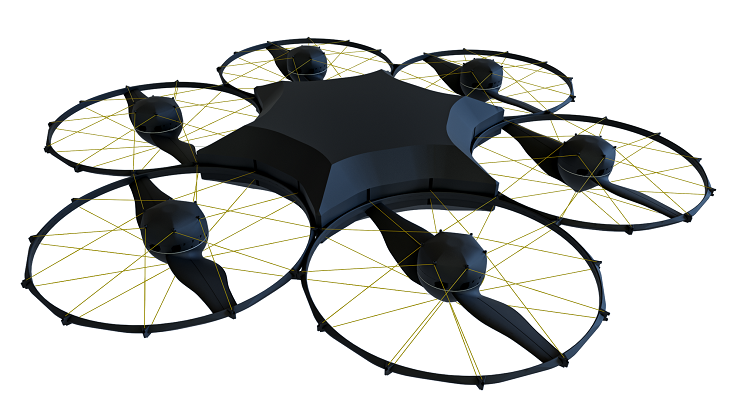

It’s born of a rather simple idea. How do we (1) make a drone more people can use, (2) in a configuration of their choosing, through (3) modular assembly as simple as any Lego set, all while (4) doubling flight time and—lastly—for a price inviting to both professional and recreational users.

The solution was the Modovolo Lift, a modularly-designed drone with 2 hours of flight time for only $6K.

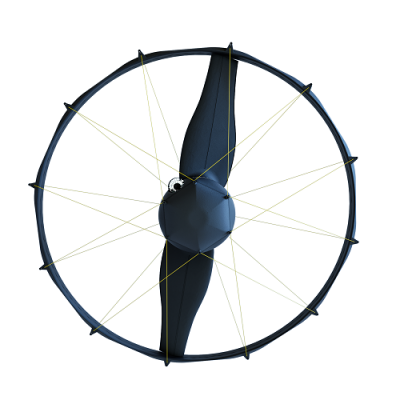

No more rigid, heavy, expensive drone rigs with fragile, open propeller blades, and 30 minutes of flying time. Instead, the Lift is a dynamic combination of lightweight design and limitless modular configuration potential, with flight time orders of magnitude longer than anything else on the market.

Modovolo looked to perfected technologies of the past—the brilliant simplicity and strength of the bicycle wheel and the convenience and fun of Lego. Strong, light, interlocking pieces, the Lift is an inspired cutting-edge innovation, a revolutionary step change in the drone category.

The efficient and powerful thrust of the Lift means bigger payloads, its spokes offering incredible structural rigidity—weighing virtually nothing—and provide laceration protection from the often dangerous spinning open propeller blades, making Part 107 compliance far easier.

It's fifty percent lighter than comparable commercial drones on the market, with fifty percent more thrust, translating to better than twice the flight time.

Modovolo is in the process of getting their first manufacturing production cell up and running. And they just launched its pre-order with delivery in early 2025 but there are only 200 slots available.

Those pre-order customers will get lots of goodies too: guaranteed production priority, special access to the Modovolo engineering team, a limited edition Modovolo t-shirt, and get to direct what kinds of Utility Pods we’ll build first.

Learn more at Modovolo.

Comments