As a drone operator myself, I’m always on the lookout for a drone with long flight-time. Because if my drone isn't in the air, then I'm not making money in my drone business.

As a drone operator myself, I’m always on the lookout for a drone with long flight-time. Because if my drone isn't in the air, then I'm not making money in my drone business.

But I’ve also needed to balance the trade-off between flight time and the cost of the drone. So far cost has been the deciding factor. I tend to tolerate short flight-time if it means less money out of my pocket.

I think the problem is that there aren’t any options. The drone industry today is divided into two different segments:

- Segment 1 There are the cheaper commercial drones at $12k and above that can maybe get up to 30 minutes of flight time with any sort of payload.

- Segment 2 Then there are the expensive commercial drones with exotic materials and designs that can get much more than 30 minutes of flight time. These are very interesting and capable but the cost can be significant. $50k to $100k+.

I’ve also been thinking about another problem: the number of drones I own. Each drone is designed to do a specific mission. If I have another mission, then I often need to buy another drone. It’s a hidden cost for my drone business.

I may be dating myself but it reminds me of the old days of the computer industry. Back in the 1970s, you’d buy a computer for a particular application. A word-processing computer; a calculator; and an account management computer. You get the idea. And you know how the story ended. You no longer purchase multiple computers, one for each application. You purchase one computer. Is the drone industry today the same as the computer industry of the 1970s? It seems like history is repeating itself.

I may be dating myself but it reminds me of the old days of the computer industry. Back in the 1970s, you’d buy a computer for a particular application. A word-processing computer; a calculator; and an account management computer. You get the idea. And you know how the story ended. You no longer purchase multiple computers, one for each application. You purchase one computer. Is the drone industry today the same as the computer industry of the 1970s? It seems like history is repeating itself.

These are the problems that Modovolo co-founders Erik, CTO (an aerospace engineer, former USAF Captain, and commercial drone pilot) and Justin, CEO (a data and tech guy who’s been an executive at 3 successful start-ups - and he’s a former intellectual property attorney) just had to tackle.

So they started a 2 ½ year stealth development journey to build a drone with amazing flight time but that was orders of magnitude less expensive than anything else on the market - and that wasn’t a repeat of the 1970s single-application computer.

“We knew pretty early on that the reason why current drones have such limited flight time is that the fixed-hub design that everyone uses is just woefully inefficient. And so just wouldn’t work.” says Erik.

Erik explains: “The fixed-hub design has so much redundant infrastructure. The arms, the legs, and the other parts needed to hold the propeller blades out from the center. And it’s a lot of extra weight.” And with a slight chuckle, Erik continued: “And the propeller blade designs are just wrong. Just wrong! They are designed for the wrong RPM range.”

“We knew we had to re-think drone design from the bottom up. A complete departure from what has been done to date.”

There have been many attempts to make drones lighter to achieve longer flight time, but these have focused on trying to improve the fixed-hub design. That has meant using carbon fiber and other expensive materials and mostly very manual manufacturing methods, all of which means a very expensive drone. That was something that Erik and Justin were hell-bent on avoiding.

“We also knew that, in order to get the cost down - way down - we needed to avoid not only expensive materials but also anything that would complicate the manufacturing process.”

That’s where the bicycle wheel became a revelation and an inspiration.

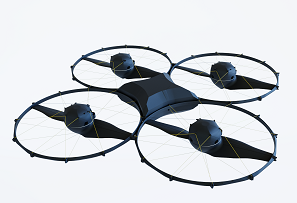

“The bicycle wheel is an under-appreciated technological marvel. It’s super light, strong, and rugged. It’s why the Lift Pods look like bike wheels. And in many ways the Modovolo Lift is a bunch of flying bike wheels connected together.”

“The bicycle wheel is an under-appreciated technological marvel. It’s super light, strong, and rugged. It’s why the Lift Pods look like bike wheels. And in many ways the Modovolo Lift is a bunch of flying bike wheels connected together.”

That’s also where the “Lego” kit idea took hold.

“After we realized that the bicycle wheel design was perfect to make a much, much lighter drone that was not only rugged and had more thrust, the next exciting revelation was the “Lift Pod” bicycle design meant you weren’t constrained to that fixed-hub design. You could connect Lift Pods together in any configuration you wanted. Need more thrust to lift a heavier payload or need more flight time? Just add more Lift Pods.”

After filing a slew of patents to protect all aspects of the Lift Pod and the modularity concept, the team came out of stealth mode just this March 2024 and launched a pre-order website.

“We’re in the process of getting our first manufacturing production cell set up and we’re offering a limited run of 200 pre-orders. Those customers will get guaranteed production priority, special access to our engineering team, a limited edition Modovolo t-shirt, and get to direct what kinds of Utility Pods we’ll build first.”

You can go here to learn more and get your pre-order today.

Comments