We've discussed the difficulties related to the amount of time that a UAV can stay in the air, but these limitations are not stopping organizations of all sizes and types from utilizing drones to perform tasks in faster, cheaper and safer ways, or from quantifying what their ROI in the technology looks like. Doing so often depends on using the right system and power source/process to keep drones in the air in order to maximize their efficiency. However, as new aircraft are added to growing fleets, the need to have more than one battery per brand/model will make the challenges associated with creating this kind of value more and more difficult.

Identifying this need, an Idaho-based company, Vertical Partners West LLC, has developed and is successfully selling a comprehensive Battery Charging Management System (BCMS) to bring order to the chaos of multiple batteries of different ages, brands and models.We reached out to Keith Wallace, CEO of VPW LLC and he enthusiastically shared with us the details of his company’s products and services. Keith is also a member of the ASTM F38 Unmanned Aircraft Systems committee, F3005-14a Specifications for Batteries for use in sUAS subcommittee and ASTM/NFPA JWG for Public Safety UAS.

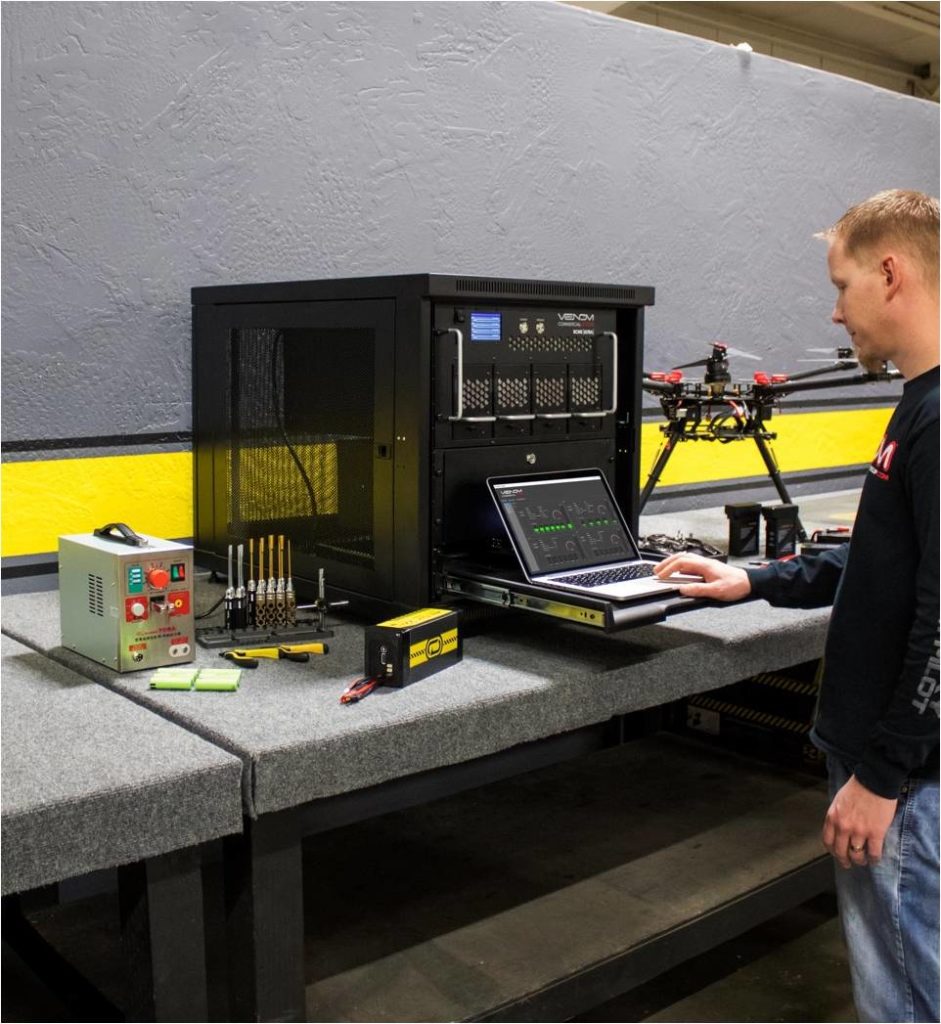

Venom Battery Management System

How do you handle the fact that most UAV batteries are of different size, shapes, weight and amperage?We created a system that would accept any type of battery and adjustable charging power from 0.1A to 22A per bay, user configurable charge and discharge profiles per battery type, 4 independent battery bays, 500mA cell balancing current and an accurate state of charge estimation. Our BCMS also records voltage, current and temperature data during discharge and controls safety features such as overvoltage, undervoltage and over temperature protection. We also added an automatic internal charge bay temperature monitoring and safety shut off built to withstand a catastrophic battery failure. Now that you mention battery safety and catastrophic events, how does your system prevent potential fires during fast charging?With battery charging safety in mind, each system has four uniquely designed, isolated charging bays built from heavy gauge steel which run along full extension drawer glides for smooth, stable operation and easy battery access. Each charger bay latches into the chassis of the charger and is coupled to an internal manifold system with heavy duty scavenging fans. With the Venom BCMS, catastrophic battery events are contained and exhausted to an external location, minimizing impact to its surroundings. Integrated temperature sensors in each bay further increase safety with user adjustable shutdown parameters to help stop a catastrophic event before it occurs.” Regarding software, how does your system helps commercial operators manage their fleet of batteries?We developed a piece of software that would allow complete control over one or one hundred chargers with a single user-friendly and intuitive interface. The system is cloud-based for quick secure access to your valuable data from any location. Automatic capture and analysis of all charge and discharge metrics provides users with nearly infinite reporting capabilities. Regulatory requirements will soon mandate record keeping for all commercial UAS operations within the national airspace and our system already provides all necessary information to be fully compliant.”While the industry waits for new power sources and a notable extension of TITA (time in the air) the solution presented by VPW LLC is a viable alternative for commercial operators with multiple unmanned platforms and a plethora of batteries, all in different stages of their useful life.

How do you handle the fact that most UAV batteries are of different size, shapes, weight and amperage?We created a system that would accept any type of battery and adjustable charging power from 0.1A to 22A per bay, user configurable charge and discharge profiles per battery type, 4 independent battery bays, 500mA cell balancing current and an accurate state of charge estimation. Our BCMS also records voltage, current and temperature data during discharge and controls safety features such as overvoltage, undervoltage and over temperature protection. We also added an automatic internal charge bay temperature monitoring and safety shut off built to withstand a catastrophic battery failure. Now that you mention battery safety and catastrophic events, how does your system prevent potential fires during fast charging?With battery charging safety in mind, each system has four uniquely designed, isolated charging bays built from heavy gauge steel which run along full extension drawer glides for smooth, stable operation and easy battery access. Each charger bay latches into the chassis of the charger and is coupled to an internal manifold system with heavy duty scavenging fans. With the Venom BCMS, catastrophic battery events are contained and exhausted to an external location, minimizing impact to its surroundings. Integrated temperature sensors in each bay further increase safety with user adjustable shutdown parameters to help stop a catastrophic event before it occurs.” Regarding software, how does your system helps commercial operators manage their fleet of batteries?We developed a piece of software that would allow complete control over one or one hundred chargers with a single user-friendly and intuitive interface. The system is cloud-based for quick secure access to your valuable data from any location. Automatic capture and analysis of all charge and discharge metrics provides users with nearly infinite reporting capabilities. Regulatory requirements will soon mandate record keeping for all commercial UAS operations within the national airspace and our system already provides all necessary information to be fully compliant.”While the industry waits for new power sources and a notable extension of TITA (time in the air) the solution presented by VPW LLC is a viable alternative for commercial operators with multiple unmanned platforms and a plethora of batteries, all in different stages of their useful life.

Comments