A new white paper discusses automated drones in mining as the next frontier; this article aims to shed light on this topic.

Mining companies are currently shifting strategy and adopting new business and operating models to include unfamiliar technologies. In particular, due to the digital revolution, it has become necessary, and significantly more cost effective, to integrate modern and developing technologies into the mining field. Currently, the traditional methods of mine surveying are conducted on the ground. However, ground based mining methods are problematic due to the danger that they expose to operators, their slow nature, and their likelihood to provide irregular results which often do not meet the needs of the operators. For these reasons alone, it is easy to understand why mining operators are turning to new technologies in order to improve results.

Automation, in particular, is one such area that can produce a significant impact and create a fully integrated and holistic digital mining environment. However, uncertainty surrounding the ability for automated technology to mesh seamlessly into the mining atmosphere has left some in the mining community weary of incorporating this new machinery.

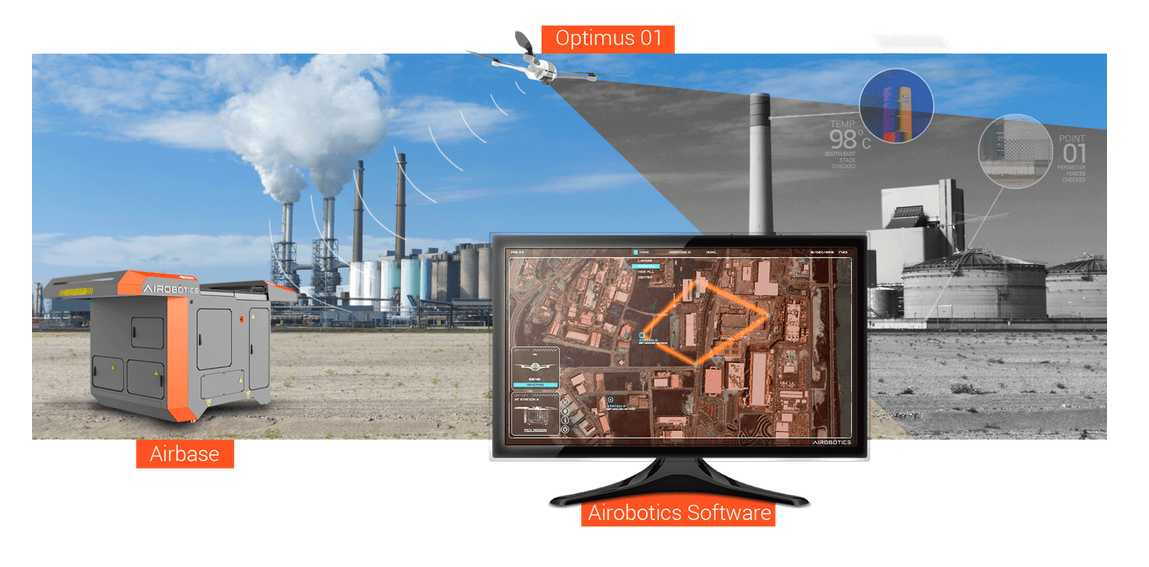

What the mining community needs in order to assimilate automated technologies into a digital mining environment is to start shifting its focus from what is happening on the ground, to what is happening in the skies. Drones, in particular, have the ability to access aerial data that was previously untapped for the mining field, and thus are already becoming increasingly accepted as a valuable commercial tool. However, one question that arises is why does the drone need to be automated in order to excel in digital mining and solve current issues with surveying or inspections?

As of right now, the use of automated

industrial drones, as one could guess, is not the only approach taken to incorporate drone technologies into the mining sphere. Generally, there are two other drone methods apart from automated systems that miners could use in order to access aerial data. The first method, drone-as-a-service, refers to the hiring of a drone operator that arrives on site with equipment in order to capture the requested data. The second method is in-house, in which the mining company will purchase hardware and software from providers and the company will operate flights manually while handling the data upload and processing itself. However, if miners would incorporate either of these methods, would the issues that they already face with ground based mining methods be solved?

The first issue facing the ground based mining methods are the danger that ground operations expose to operators. With drone-as-a-service, one could argue that the hiring of an outside contractor could be unreliable and expose the mine workers to an unnecessary risk

. In comparison, using in-house methods would also be dangerous to incorporate for on-the-ground workers, because someone in-house may not be completely trained to handle a drone within a mining environment. Thus neither using drone-as-a-service or in-house drone methods completely protect workers on the ground. Safety is one of the most important improvement factors for mines, hence the need to constantly keep personnel safe and protected is a prime one.

The second issue facing the ground based mining methods is its time consuming nature. With drones-as-a-service, the mining company would only be able to complete one or two missions per day, which may be a small step-up from ground data, but is still ultimately inefficient in terms of collecting a large amount of data. Additionally, with in-house drone technologies, on average only two missions can be conducted per day, which once again does not provide mining companies with a large advantage. The problem still stands, neither using drone-as-a-service or in-house drone methods can completely solve the time-issue to generate needed data.

Finally, the third issue facing the ground based mining methods is their tendency to provide irregular results, which often do not meet the needs of the operators. First, with drone-as-a-service, there is the possibility that the service may not understand fully the needs of the company, and thus they may not provide the best results. With in-house, on the other hand, while the person operating the drone may understand the demands, user error can play a huge role in the mining company not getting the results they need. Thus once again, neither using drone-as-a-service or in-house drone methods would completely solve the problem of irregular results.

Additionally, with both drone-as-a-service and in-house drone services, cost is an important factor. With both methods, an operator still needs to be hired to manage and handle the drone, which is the most expensive factor in drone use. Ultimately, both drone-as-a-service and in-house are not scalable due to the high cost of hiring a drone operator.

However, where drone-as-a-service and in-house drone methods are lacking, automated drone services have the ability to succeed. With automated drones, miners can reduce human error that occurs with drone flight, while also provide companies with unlimited and fast paced measuring, surveying and maintenance inspection. Ultimately, an automated system excludes the logistics, mission delays and operator involvement that would allow for twenty-four hour availability. By eliminating a pilot, automated drone services would improve reliability and safety, will dramatically increasing efficiency and availability. As an added bonus, the automated solution will prove a much higher return on investment than any of the other methods.

Ultimately, an automated drone system addresses the increasingly important role of regular, reliable data collection as well as a host of other issues currently encountered with data harvesting in the mining environment.

To learn more about automated drones in mining, download this white paper.  The second issue facing the ground based mining methods is its time consuming nature. With drones-as-a-service, the mining company would only be able to complete one or two missions per day, which may be a small step-up from ground data, but is still ultimately inefficient in terms of collecting a large amount of data. Additionally, with in-house drone technologies, on average only two missions can be conducted per day, which once again does not provide mining companies with a large advantage. The problem still stands, neither using drone-as-a-service or in-house drone methods can completely solve the time-issue to generate needed data.Finally, the third issue facing the ground based mining methods is their tendency to provide irregular results, which often do not meet the needs of the operators. First, with drone-as-a-service, there is the possibility that the service may not understand fully the needs of the company, and thus they may not provide the best results. With in-house, on the other hand, while the person operating the drone may understand the demands, user error can play a huge role in the mining company not getting the results they need. Thus once again, neither using drone-as-a-service or in-house drone methods would completely solve the problem of irregular results.Additionally, with both drone-as-a-service and in-house drone services, cost is an important factor. With both methods, an operator still needs to be hired to manage and handle the drone, which is the most expensive factor in drone use. Ultimately, both drone-as-a-service and in-house are not scalable due to the high cost of hiring a drone operator.However, where drone-as-a-service and in-house drone methods are lacking, automated drone services have the ability to succeed. With automated drones, miners can reduce human error that occurs with drone flight, while also provide companies with unlimited and fast paced measuring, surveying and maintenance inspection. Ultimately, an automated system excludes the logistics, mission delays and operator involvement that would allow for twenty-four hour availability. By eliminating a pilot, automated drone services would improve reliability and safety, will dramatically increasing efficiency and availability. As an added bonus, the automated solution will prove a much higher return on investment than any of the other methods.Ultimately, an automated drone system addresses the increasingly important role of regular, reliable data collection as well as a host of other issues currently encountered with data harvesting in the mining environment. To learn more about automated drones in mining, download this white paper.

The second issue facing the ground based mining methods is its time consuming nature. With drones-as-a-service, the mining company would only be able to complete one or two missions per day, which may be a small step-up from ground data, but is still ultimately inefficient in terms of collecting a large amount of data. Additionally, with in-house drone technologies, on average only two missions can be conducted per day, which once again does not provide mining companies with a large advantage. The problem still stands, neither using drone-as-a-service or in-house drone methods can completely solve the time-issue to generate needed data.Finally, the third issue facing the ground based mining methods is their tendency to provide irregular results, which often do not meet the needs of the operators. First, with drone-as-a-service, there is the possibility that the service may not understand fully the needs of the company, and thus they may not provide the best results. With in-house, on the other hand, while the person operating the drone may understand the demands, user error can play a huge role in the mining company not getting the results they need. Thus once again, neither using drone-as-a-service or in-house drone methods would completely solve the problem of irregular results.Additionally, with both drone-as-a-service and in-house drone services, cost is an important factor. With both methods, an operator still needs to be hired to manage and handle the drone, which is the most expensive factor in drone use. Ultimately, both drone-as-a-service and in-house are not scalable due to the high cost of hiring a drone operator.However, where drone-as-a-service and in-house drone methods are lacking, automated drone services have the ability to succeed. With automated drones, miners can reduce human error that occurs with drone flight, while also provide companies with unlimited and fast paced measuring, surveying and maintenance inspection. Ultimately, an automated system excludes the logistics, mission delays and operator involvement that would allow for twenty-four hour availability. By eliminating a pilot, automated drone services would improve reliability and safety, will dramatically increasing efficiency and availability. As an added bonus, the automated solution will prove a much higher return on investment than any of the other methods.Ultimately, an automated drone system addresses the increasingly important role of regular, reliable data collection as well as a host of other issues currently encountered with data harvesting in the mining environment. To learn more about automated drones in mining, download this white paper.

Comments