Just like in many other industries, drones in Energy & Utilities provide faster, more efficient, and safer methods for asset inspections, perimeter security, and progress monitoring. Companies can apply drones to their workflows in a variety of ways, but there’s one that’s been of growing interest: Drone in a Box (DiaB).

DiaB solutions are already being used to streamline operations for solar farms, pipelines, dams and hydropower, gas power plants, grid substations, and more. They are door openers for more automated operations, and possibly BVLOS flights. Continuing from our Drone in a Box Solutions for Construction article, this one focuses on the specific offerings of DiaB solutions within the Energy & Utilities sector.

Since many of the available solutions easily adapt to various industries, some of the ones listed here have already been mentioned in our previous article. For those, we will discuss how they are being used in Energy & Utilities, instead of what makes them stand out.

Exabotix

Germany-based Exabotix, a drone developer, manufacturer, and marketer, is developing and manufacturing fully automated DronePorts, a DiaB solution, for automated inspection and monitoring.

Since the company is behind the manufacturing of both the DronePort and its drones, all devices are interconnected, and the ecosystem allows for full fleet remote control. The drones can fly up to around 43 miles from the dock, and by installing an optional module, they can fly from one dock to the next to cover longer distances. The dock is fully air-conditioned, enabling it to operate 365 days a year, 24 hours a day. In addition, it features a weather station to ensure that flights can be planned and executed safely. Moreover, each dock connects to the others to include their data in the calculations of weather conditions.

According to Alexander Helbing, Founder and Managing Director at Exabotix, using a DronePort reduces costs from around $26,000 to $20,500 for a single annual solar plant inspection. The DronePort costs around $82,000, meaning it would pay for itself after five years at the latest, and save almost 30% of costs over ten years. On top of that, the annual costs of the system do not increase due to additional inspection flights, significantly increasing ROI when compared to conventional methods. For other facilities, such as pipelines or routes, Helbing points out how operators usually use helicopters for inspection, which can cost $550 and upwards per hour, and their purchase prices are above $330,000. In these cases, a DronePort would pay for itself even faster.

DJI Dock

In 2022, DJI introduced its DiaB as “a game changer for the drone industry and a significant step towards achieving true autonomy in drone operations”. Following that statement, they presented how the DJI Dock can increase ROI for Solar PV Inspections.

For a 100MW solar farm, neglecting inspections throughout the year could incur an annual loss of up to $140,000 due to reduced power generation. Employing a ground crew of two individuals to manually inspect the farm entails approximately five hours per MW, totaling 65 days to cover the entire farm. Conducting inspections biannually could result in expenses of around $120,000 per year. Alternatively, with the DJI Dock system, which requires an initial investment of roughly $45,000 for hardware and deployment, coupled with third-party inspection analysis software, companies can conduct a minimum of 12 inspections annually. DJI claims this approach offers consistent and timely feedback, potentially doubling cost savings compared to traditional manual methods.

In 2023, Enel Green Power, a provider of electricity and gas, conducted the first-ever solar farm inspection in the US. Together with DJI, Raptor Maps, a software developer for the entire solar lifecycle, and Unmanned Vehicle Technologies (UVT), a US drone and robotics dealer, Enel Green Power conducted the landmark inspection at an 181 MWdc solar site in Texas. Using the DJI Dock, the company demonstrated its ability to facilitate inspections on a utility-scale site.

“There are a lot of operational considerations, such as pilot access to the site, data offload, and on-site flight planning, that are simplified with the DJI Dock,” said Grant Hosticka, DJI’s Head of Enterprise Solutions Engineering, North America. “The Dock automates operations and allows for repeatable methods of data collection, which we believe will change the face of solar inspections.”

RocketDNA

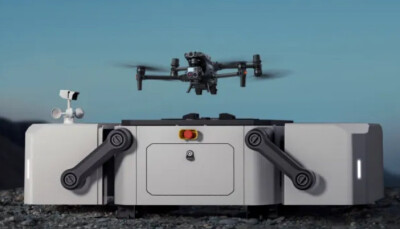

Designed to automate operational workflows using drones and AI, RocketDNA’s DiaB solution, xBot, “creates safer and more sustainable work environments by using our autonomous drone-based, remote geo-data solutions”, said RocketDNA CEO, Christopher Clark. xBots allow companies to detect leaks, intrusions and theft along pipelines and critical energy installations, providing pro-active surveillance and inspections.

“One of the main issues with electricity outages for example is the fault can be difficult to locate, especially in remote areas where the fault may be a fallen tree over a power line miles away from a road,” Clark stated. “RocketDNA’s drones-in-a-box respond automatically when a fault occurs and can be used to identify the exact location and send the information back to the remote operating center (ROC) in a much more timely and efficient way. That could help utility companies dispatch repair crews faster and get customers back on supply sooner.”

xBots can also identify faults on pipelines and conveyor belts, corrosion, overheating, and defect detection of critical energy infrastructure, to full emergency response.

The company’s autonomous flight footage and remote detection plus AI overlay are recorded and live-streamed in real-time, helping organizations simply and urgently determine the issue and the appropriate level of response.

The company secured an autonomous BVLOS operations approval from the Australian Civil Aviation Safety Authority (CASA) last year, becoming the first drone operator in Australia with approvals for the DJI Dock. The approval also includes Hextronics’ Global Drone Station.

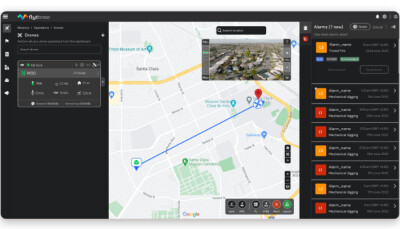

FlytBase

Pampa Energía, an Argentina-based independent energy company, produces about 4,970 MW of electricity through wind, hydroelectric, and thermal power plants. From tanks and chimneys to high-voltage towers, boilers, and electric grids, it is crucial to ensure that assets are functioning correctly, as issues like corrosion or lateral structures near the pipeline often go unnoticed during a manual drone inspection.

To inspect and conduct perimeter security tours of Pampa’s 970,000 square feet power plant, inspectors would take more than a day, and security had to constantly set up their base station, replace drone batteries, and transfer data manually after a certain distance. For that reason, the company decided to explore the use of autonomous DiaB with FlytBase to simultaneously carry out maintenance planning, inspections, and security operations.

“By using autonomous drones for these inspections, energy companies can increase efficiency and safety for workers and reduce any potential downtime of the plant,” said Achal Negi, Director of Business Development at FlytBase. “Furthermore, the use of automated drones for thermal power station inspection with drones and docks offer more frequent and thorough inspections and also improve night-time security operations for power stations.”

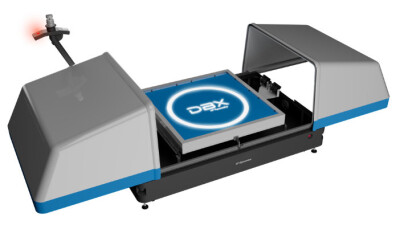

H3 Dynamics

While H3 Dynamics’ solution targets a variety of industries, the company’s 2022 DiaB launch, DBX-G7, was focused on the construction and monitoring of solar farms of all sizes. Using scanner drones with thermal cameras and HD cameras on board for PV panel anomaly detection, the company claims the drone-agnostic DBX changes the way data is captured and processed throughout the entire lifecycle of solar power assets.

By partnering with Sitemark, H3 allows users to create cloud-based digital twins of their sites and remotely analyze data in real time to diagnose anomalies quickly. With the help of AI, the system pinpoints specific PV panels causing production issues to help understand root causes and provides instant estimation of the yield and revenue loss associated with those anomalies.

During the construction of a PV site, Alinea Solar, a renewable energy specialist, used a drone to identify a 50-foot crack that could move structures, causing panels to fall and break. Using Sitemark’s historical data, the team was able to analyze and compare pre-earthworks and current data to come up with corrective measures to fix the issue. This led the team to avoid damage to the structures and tables, as well as prevent potential blackouts, saving up to around $16,000 in repairs.

Comments