We’ve explored how large and small construction firms can use drones to create efficiencies of all types, but that’s just part of the reason that an article that detailed how a prominent general contractor used drone technology to significantly improve the safety and accuracy of their surveys caught our eye. Questions about what it actually means to adopt the technology are always top of mind for users, which is why the approach Ames Construction took with drones that allowed them to save time over their traditional topographic methods was so illuminating.

Ames Construction does business largely in the heavy civil construction realm but their work ranges across a large spectrum of projects and clients. Specifically what they do, how they work and who they are have been laid out in detail on their site, but their reputation as a full-service, heavy civil and industrial general contractor that operates throughout North America is recognized across the region.

Insights from Tanner Richards, project engineer at Ames Construction, were highlighted in the article that detailed how the company created efficiencies with drones but we wanted to learn more about that process and how the company is measuring the value of the technology. We caught up with him to learn more about how Ames Construction approaches the adoption of new tools, whether they had to hire new staff to operate their drones, how he envisions the technology will be utilized by the company in the future and much more.

Jeremiah Karpowicz: What’s an example of one of your biggest or most notable projects?

Tanner Richards: That’s a hard metric to measure as all our projects tend to serve a greater function than ourselves and clients. A lot of our work is highway infrastructure and therefore tax funded. One could argue any work in this realm is immensely valuable considering the ROI that investing in a country’s infrastructure has.

That being said, I find our most notable projects to be disaster works projects (we’re particularly good at earthwork projects including any mudslide operations or highway uncovering operations) or power plants/dams. They’re just at a grand scale compared to other more mundane road projects or reservoirs etc. I also find our mine work very interesting because I lived it for years. The scale of things on copper mines in Arizona and elsewhere is amazing. Where our work and projects are year to year varies a lot just depending on the natural ebbs and flows of the market and needs of our potential clients.

At the end of the day we excel heavily at built structures and moving earthen material. We also have a significant fleet to meet these ends.

How does the company as a whole approach the adoption and integration of new technology?

I would say Ames has always been a pioneer of bringing new solutions to our customers in an old industry. A lot of means and methods are set in their ways but Ames has shown to be a leader in adopting technology that gives us insight and added value to our projects—our drone program being just one example.

Ultimately, the work is accomplished in the field at the ground level and often times with significantly expensive equipment (large excavators or dozers etc) so our ability to capitalize on innovation strikes highest there. This realm of heavy equipment has been ‘futurized’ to ever increasing degrees as more and more GPS technology comes out to adapt to them. Our fleet of GPS dozers and motorgraders can accomplish significantly more work (and in less time) than conventional methods, not to mention the reduction in the amount of rework we have due to the survey accuracy tied into the equipment.

Were the biggest challenges associated with your adoption of drones related to the technology itself or to establishing new processes and procedures?

I wouldn’t say it is an either/or, but an inextricably fused answer.

The technology enables me to make many decisions. Without experience and training, it’s easy to get it wrong. For example, huge challenges still remain around creating consistently-accurate results. Is the difference in GSD giving me worse data in certain areas? Do we need to adjust the data acquisition, data manipulation, or other processes? What will the effect be if we make minor adjustments to the camera settings for sensing different terrain with different textures and heterogeneous ground conditions?

All of these questions have answers within reach, but it does take some trial and error and a good bit of study within the science of photogrammetry. What I’m getting at is one of the best parts of my job is that it’s always challenging and a problem solving effort. Each project and flight is a new puzzle to solve in the best way possible to get the most accurate survey possible. I enjoy this challenge of merging technologies to achieve a goal (cm level accuracy survey consistently) as well as the general challenge of using drones in the workplace and bringing drones to the forefront of the industry and illustrate just what they can do for our business.

The other looming challenge continues to be a lack of clear legislation or guidance from regulatory agencies in the US. Drone regulation progress seems to be lagging behind the blisteringly fast expansion of drones worldwide.

Did you need to hire new staff or outside contractors as part of this adoption process, or was it more about training for your current staff and contractors?

Initially this was more of a retraining and bringing more responsibilities under one centralized role. Having staff available that was survey knowledgeable and already handling GPS equipment for our heavy fleet, it was a natural fit to include the drone program in our survey capabilities. It was really just adding the tools and capability to our toolbelt more than anything.

Admittedly, there is a lot of tech savvy and specific knowledge that goes into our drone program (and survey program as a whole for that matter) so it’s definitely training intensive as well as getting used to thinking differently and problem solving differently. Still, the cost benefit has been overwhelmingly positive in regards to returns for us. Being able to keep better tabs on our work and to have accurate and provable quantities of material moved helps us get paid the fair amount every time.

Can you tell us about the process and logistics associated with your traditional approach to topographic mapping methods? When and how did you realize drones could change and improve these methods?

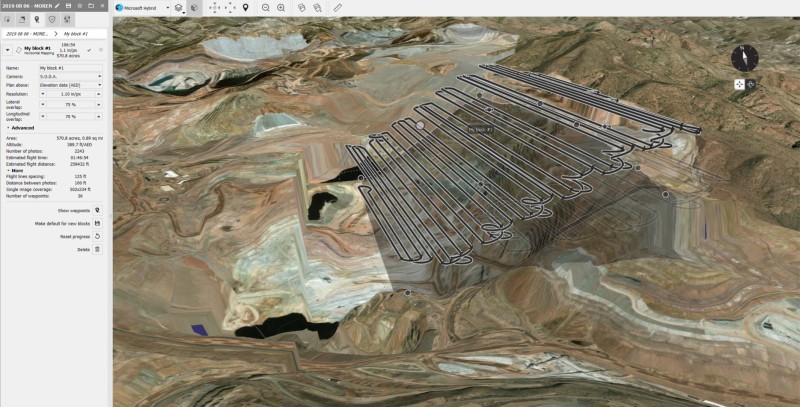

I guess I’d just point you to a standing surveyor or grade checker if I were to show you our traditional approach to topographic mapping. Good old-fashioned walking and shooting grids. Depending on the project, our survey team would feel blessed with a 20 to 100 foot grid. It just depends on what the specifications of the project dictate typically. However, adding drone level precision we’re able to get super accurate models. We can also incorporate survey from the field to further supplement and refine our models.

The drone is able to meet any spec for field topo level accuracy (aside from high accuracy bridge or structural work of course) as well as help us build our as-builts and track our work and billings. I believe it was about 6 years ago when we first partnered with senseFly and began using their drones to map our projects regularly. Since then, drone mapping and technology has only gotten better and smarter all around.

What does it mean to a project when operations need to be temporarily shut down to allow surveyors access to the site to perform their work?

Now this is a very case dependent question as well. The answer depends on the particulars of each scenario.

On the majority of our projects, we have access control and right of way delineated to protect our work and workers. Typically our surveyors have reasonable access to areas they need to get to, or else we can shift equipment or operations long enough for them to accomplish what they need to do. Other times they will need to accomplish their surveying when they can (after shift, at night, etc.) to avoid interrupting crucial work. It really just depends on access and needs.

Shutting down a project to complete survey work can be mildly obtrusive or extremely. We prefer the former but sometimes the latter is needed. The beauty of the drone is that no operations need to stop.

Does a drone give you everything you need in these situations? That is to say, can you still get everything you need via drone without shutting things down?

You may have some slight error in quantities if the survey is accomplished during operations but this is negligible and drone flights can only occur in certain daylight windows so working at night isn’t an option anyway. Luckily the drone doesn’t mind ongoing operations.

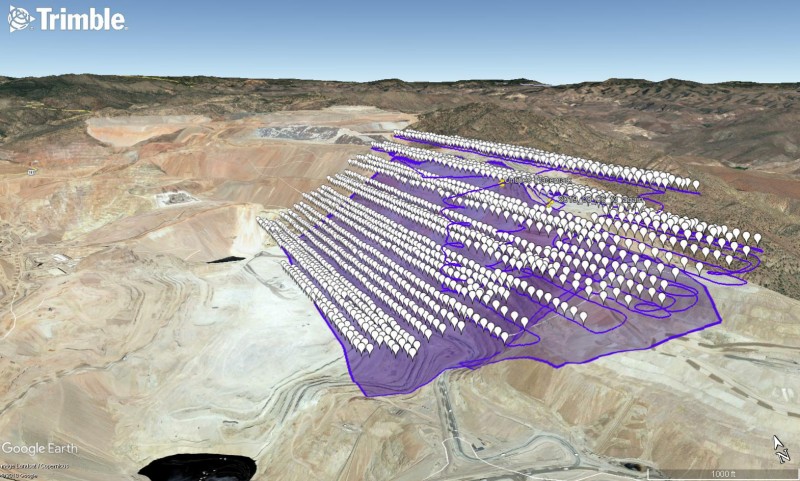

Certain sites, like the pit wall investigation I’ve answered questions about before, are not only inaccessible due to work on the pit wall benches, they’re also a nightmare of a safety hazard to address. It’s a whole operation to get access to monitoring wells or other points of interest on some of the wall benches because they are inherently very dangerous. Any slope failure or slippage could be catastrophic for anyone daring enough to venture out on these benches. Enter our drone. Able to safely fly above and terrain follow the wall all the way up and down. Accurately mapping the whole face and surface of the wall, all while minimizing risk and bodily harm down from ‘potentially catastrophic and loss of life’ to ‘maybe we need to buy a new drone now’ levels. No need for crazy safety and access plans. No need for shutting down work areas or equipment to help ensure other vibrations or work going on doesn’t jeopardize the safety of this high risk maneuver they’re trying. It’s really becoming more and more of a no brainer to let drones and machines be our arms and legs in otherwise very dangerous scenarios.

That ties into how your use of drone technology allowed you to better evaluate and implement new safety. Are those distinctions that show up in the bottom line? If not, where and how are they measured?

I would say in this instance these distinctions showed up in the bottom line for our client instead. Yes, we are paid to accomplish these surveys and our other work for the client, but I believe what it provided them was peace of mind and clarity as they went about developing their plan to address any issues or future planning and expansions.

I think typically safety is a hard metric to measure in terms of cost saving. That being said, this small investment in analysis will yield huge returns in the future in regards to safety and production. This gives them a clear path forward as they address mining plans and safety simultaneously (as always). They needed an innovative way to evaluate their wall and we gave it to them.

We use our drone flights extensively for planning. Not just planning our work but also safety planning. Planning emergency routes in case of accidents. Muster points. Creating maps and distributing and posting them onsite. Calling out active hazards and changing conditions. The drone flights allow us to essentially update Google Maps whenever we want. If conditions change on site because we moved a mountain from one place to another or dug a lake then we can fly and update that visually on our maps. The potential is unending for what drones can help us with.

Using a drone allowed you company to better handle the administrative hurdles that are typical of a large construction site. Are such hurdles the main drivers for a project staying on time and coming in under budget?

Oh, they areabsolutely huge drivers. I don’t want to be quick to say they are the main drivers but you can definitely tell a well-managed job from a poorly managed job and it isn’t always just how the bottom line looks.

All information and decision-making starts in the office and filters to the field. Because of this, the office staff needs to understand and intimately know exactly what’s going on with the project currently, how it’s trending, issues/impacts, and progress reports to name a few major categories of concern. Regular drone progress flights give them half this information in a concise package. They’re able to track their work accurately. They’re able to visualize and see potential issues and obstacles during construction and in live time. Not having a good handle on your project can doom the profitability of it. Having access to the data our drone provides is just one extra guarantor and tool to help the project succeed.

Keep in mind, no work will be getting done if the office isn’t on top of things and knocking down roadblocks ahead of time that are coming up to derail the project.

What are some of the unseen or seldom talked about benefits of your use of drone technology?

That ties into something bigger, because I like to believe that people appreciate good work and good intentions. I truly believe our clients know that we’re here to get them the best value for their dollar and to that end, we try to be transparent throughout. Our survey and drone program has been one such way. By building good faith through honesty and by having irrefutable survey evidence in your backpocket should honesty fall through!

One other thing to keep in mind too is that we deal with several entities on any one project, not just the client. So showing the client we’re transparent and on their side typically is in our best interest, not just for successful completion of the project, but in hopes that they’ll think of us the next time they have problems that need solving or projects that need built.

How do you envision Ames Construction will continue or expand upon the use of drone technology over the next few years?

I don’t want to speculate too much on the future but I believe drones serve a vital function for Ames, especially due to the nature of our work and the fact we’re a large player in the earthwork market. It behooves us to have survey mapping technology considering we’re changing the landscape of the ground constantly and need to be able to measure it. I believe there are diminishing returns eventually to every technology but I don’t believe we’ve hit that point yet when it comes to drones at Ames Construction.

I believe they will play an ever increasing role up to a point, but again, everything tangible is accomplished at ground level in the field at Ames Construction. I’m happy to be one of many support players at Ames that help us succeed and build every project safe.

What’s one piece of advice you have for anyone who believes their organization could benefit from utilizing drones but isn’t sure where their adoption process should begin?

Firstly, educate yourself. It may seem daunting or like a new industry but there is an abundance of information out there about drones and what they can do for you. Additionally, I would say listening to reading/absorbing case studies such as my own can be enlightening and you may even find one surprisingly similar to your own specific-use case. I know that drones can be useful in just about any industry or workplace but I also realize my application is somewhat niche/specialized.

My main advice would be jump in. See what capabilities and options you have and just try it. Don’t invest in a drone program with no one capable to oversee or run it though. You’ll need someone capable and ambitious along with your own goals and deliverables for that program itself. I believe most companies could handle this ‘exploratory investment’ and couple it with or assign these duties to someone with another role already that is able to do both and willing. Like a test case of sorts. Let this run for a month or two and see if there isn’t progress or a value gleaned from this test run.

My other piece of advice is to lean on the tech knowledge of others. Many in the workplace nowadays wouldn’t be able to take up a drone program and harness it in a month or two. The tech skills sadly aren’t there. Find someone that is eager and willing to continually devote the time to bettering their own tech skills in order to help the drone program run smoother.

Comments