Last month, Flyability and WinCan announced a partnership to streamline and improve sewer inspections. Working together, the companies are creating a custom integration between Flyability’s Elios 3 drone and WinCan’s Web solution that will enable the conversion of drone-captured sewer data into industry standard-compliant reports.

Specifically, the two firms seek to fly the Elios 3 into sewers to capture data that can be uploaded to Flyability Cloud and imported to WinCan Web. While the Elios 3 is already active for sewer inspections, this development will allow inspectors to review assets and inspect points of interest in a timelier manner. Additionally, inspectors can use AI-powered defect coding enabled by WinCan Web to efficiently categorize defects or maintenance issues.

While the partnership was born of the desire to provide Elios 3 users with a workflow that takes them from flight to final report as easily as possible, harnessing the power of the data being collected in any context is about expectations as much as it is technology.

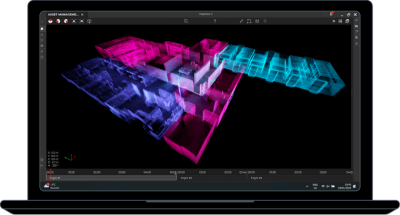

“Data management is a challenge in any industry,” said Eloise McMinn Mitchell, Content and Communications Manager at Flyability. “You can have hundreds of gigabytes of information but no way to manage or analyze it. With the Elios 3, you can get incredibly detailed data through both 4K visual inspections and centimeter-accurate lidar scans, but if you don’t have an optimal way of managing that data, you can’t take full advantage of it. Knowing how to best package and present the data is something some users can struggle with, and we’re doing our best to ease that process to make inspections and reporting simpler.”

While Flyability already provides a piloting app called Cockpit and an analysis software called Inspector, being able to solve specific challenges like the ones present in sewer and wastewater network inspections is a priority for the company. It’s why Flyability has been actively exploring software partnerships like this as it allows the company to offer greater usage and applications to users in such specific industries, and for precise applications.

Doing so has allowed the company to develop this full solution for drone-based sewer inspections. That’s a distinction which makes a difference to users that otherwise need to customize the tools in ways that can be a challenge to replicate or scale.

“A full solution means there are no gaps between the data collection, analysis, and reporting stages,” McMinn Mitchell told Commercial UAV News. “We’re making it possible for Elios 3 users to manage their data in a process optimized for the sewer inspection application. In the past they may have collected great data with the Elios 3 but had no way to present it to sewer managers in a format they’re used to. Now, we’re offering users of the Elios 3 and WinCan the chance to combine their detailed data collection with tailored analysis that is designed for sewer management. Points of interest (POIs) that the pilot identifies during the flight are automatically transferred so the person analyzing the data can see what the inspector noticed on the ground. It streamlines communication and simplifies the data management process.”

Beyond timesaving, this new process will offer many other benefits to sewer inspection professionals. WinCan Web will automatically calculate where a defect or point of interest is compared to the point of entry. WinCan also uses AI to automatically detect defects, which saves users time during analysis.

The new system also addresses key issues related to report-generation that are in line with industry standards. WinCan supports over 30 different observation catalogs, which is more than any other sewer inspection software company. Standardized protocols like NASSCO's PACP, MACP, and LACP facilitate consistent interpretation across various regions and regulatory environments, expanding its applicability.

For Flyability, this collaboration with WinCan— the first company ever to make software for wastewater pipe inspections—demonstrates the company’s commitment to improving sewer inspections and adapting its drones for new and more effective operations.

“The partnership further proves the value of the Elios 3 for sewer inspections,” McMinn Mitchell stated. “People have already been using our drone to collect data but now they’re able to integrate it with existing workflows and see it in the format they are already used to. This means that network managers can get more data than was previously available but still analyze and present it in the same way. The Elios 3 was already a game-changer for sewer inspectors looking to make inspections faster and safer, and now they can convince skeptics by showing the data is already accepted by a major industry player.”

Comments