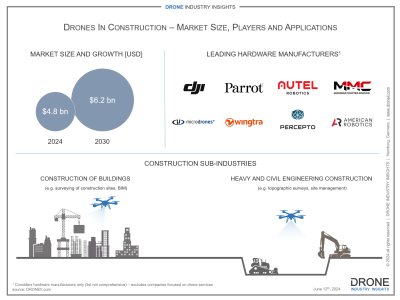

Drones have become increasingly impactful in the construction industry, offering a range of benefits that improve efficiency, safety, and cost-effectiveness. In 2021, the global construction drone market had a revenue holding of $4.9 billion, growing to $6.01 billion in 2023. With the adoption of 5G technology, the rise of DaaS models, smart cities, remote work, and a growing emphasis on sustainability, it’s expected that the industry will reach $12.27 billion by 2028.

From less common applications, such as Security Monitoring, Envelope and Volumetric Surveys, to more prominent ones, like As-Built Documentation, Surveying, Promotional Videos, and Progress Photos, drones are used in a variety of ways across the Construction industry. In the “An Overview of Drone Applications in the Construction Industry” article, published last year, Seoul National University of Science and Technology goes into detail on how companies can apply drones to the design, construction, and maintenance phases of a project.

Earlier this year, we discussed how Kuhn Construction, a family-owned and operated company, is using drones to inspect multiple churches in the Episcopal Diocese of Missouri. This is one example of how drones may provide an advantage over traditional methods, but how are other companies and researchers applying drones to their projects?

Theater Renovation

During a renovation project at a former theater in Arlington Road, Camden, London, Vertex Access faced some challenges, such as inaccessibility of critical areas, and insufficient data from terrestrial scanners. As an industrial rope access specialist in surveying, maintaining, or repairing buildings and structures, Vertex found that drones could help them surpass the previously mentioned issues.

Using an Elios 3, Vertex managed to perform an entire survey of the site within just one hour, collecting detailed visual data of all the inaccessible areas. To visualize and analyze the building's current condition effectively, the company produced an accurate point cloud of the structure, and high-resolution video footage to identify and prioritize areas requiring immediate attention.

In-Flight Building Repairs with Bee-Inspired Drones

Inspired by the natural building techniques bees and wasps use, researchers including Weitzman's Robert Stuart-Smith have developed a swarm of drones that can collectively 3D print material while in flight.

Called Aerial Additive Manufacturing (Aerial-AM), the system uses a fleet of ScanDrones and BuildDrones working together. ScanDrones perform ongoing quality checks, consistently evaluating the work of BuilDrones, and providing insights into the next manufacturing steps. After receiving the new steps by ScanDrones, BuilDrones will transport and deposit materials while flying.

According to Weitzman's Robert Stuart-Smith, this may not only enable unbounded manufacturing for building, but also for repairing structures, including in difficult-to-access or dangerous locations such as post-disaster relief construction, tall buildings, or infrastructure.

Concrete Operations with Drones and AI

During a 31-story mixed-use project, Juneau Construction knew that using handheld laser scanning 24 hours before concrete pours wouldn’t leave them enough time to make any necessary corrections, like misplaced sleeves. The solution was to use drone capture before concrete pours, outputting documentation to inspect and report on deviations. However, that would still take around 10 man hours per pour, and a single misplaced, out of tolerance, or missing sleeve can take up to $2,000 reword cost. For that reason, Juneau looked into DroneDeploy’s Concrete Sleeve AI Report.

As an intelligent reporting tool to identify critical issues before pouring concrete, Concrete Sleeve AI Report analyzes drone ortho maps against a coordinated plan and delivers detailed analysis. Leveraging AI and machine learning, companies can detect and address potential issues early on, ultimately saving the project time and resources. In Juneau’s case, DroneDeploy’s tool enabled the team to perform aerial inspections in 10 minutes and generate reports in 2-4 hours. By freeing up almost 10 man hours per report, the company saved an additional $40,000.

Drones Help to Put an End to an 80-Year Debate

Subject of debates and studies since 1950, the Bogotá Metro is a massive transportation project featuring a 14-mile line with 16 stops. In 2019, a contract was finally signed, and construction of the first metro line began in 2021. However, the use of traditional methods for soil excavation analysis and calculations resulted in delays and budgetary setbacks of the train depot’s construction.

To counter these difficulties, Xenital, a Bogotá-based civil engineering company overseeing the construction, used drones, photogrammetry, and Pix4D to demonstrate the time and speed advantages of these technologies. Using a DJI M300 equipped with a Zenmuse P1, the company captured the job site’s terrain in 45 minutes and processed the dataset in less than two hours using Pix4D. What would take around 20 days to complete using traditional methods, was now delivered in less than a day, streamlining the process by more than 500%, and providing error rates of less than 1%.

In conclusion, drones are becoming indispensable tools in the construction industry, revolutionizing various aspects of project management and execution. The examples highlighted in this article illustrate the industry’s rapid growth, reflecting the increasing recognition of their benefits in enhancing efficiency, safety, and cost-effectiveness.

Comments